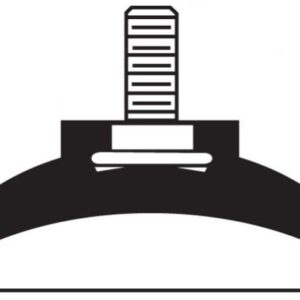

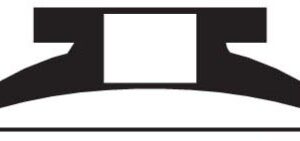

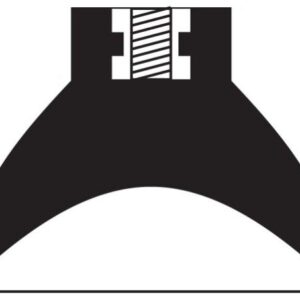

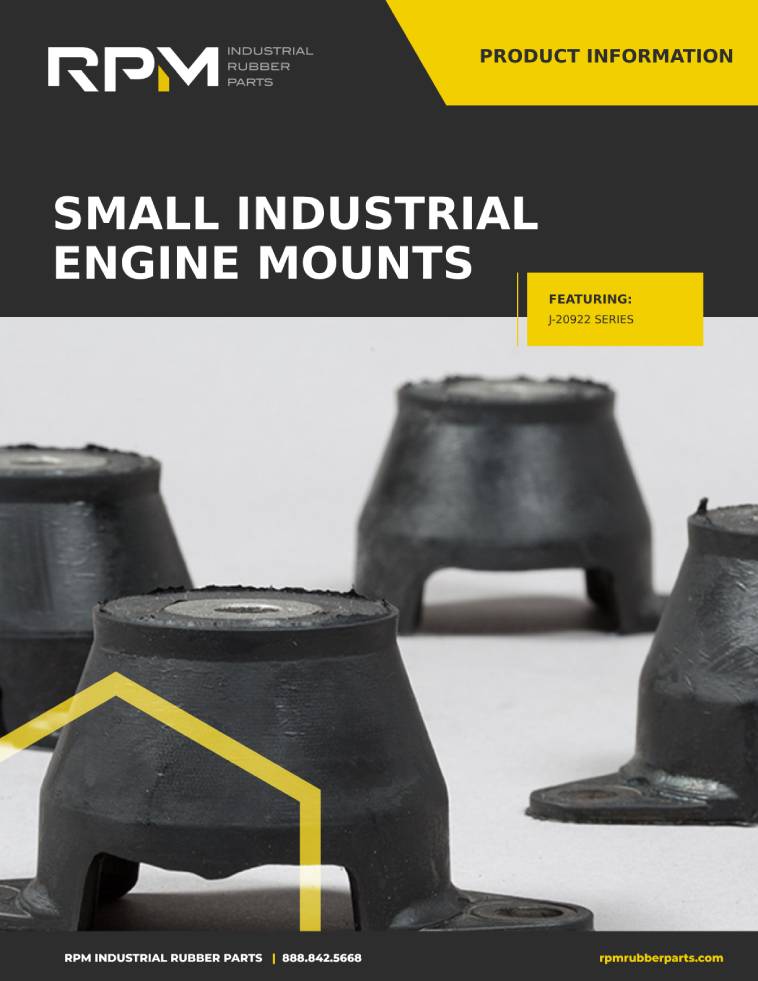

Engine mounts are one of the most important parts of any automobile or motorized system. These parts work to hold the engine in place. They also reduce vibration and noise that may come from the engine. Engine mounts keep your engine from getting damaged and keep operators comfortable and safe in the vehicle.

When purchasing a standard engine mount or ordering a custom one, it’s important to know what kinds of materials are best suited for the part and application. Engine mounts are made out of rubber with a metal bolt or attachments.

Custom Rubber Molding Processes

Whether the part is prototyped or reverse engineered, the molding processes are the same.

Take a look at four of the best engine mount rubber materials:

1. Natural Rubber

Natural rubber is one of the most commonly used polymers in engine mounts. This is mostly due to its excellent resiliency or rebound characteristics – the ability to return to its original shape. Natural rubber has many other benefits. These include high tear and abrasion resistance as well as excellent water, acid and temperature resistance.

However, although natural rubber is a great material for engine mounts, it does have its shortcomings. Natural rubber does not have a high resistance to gas, ozone and flames. The low flame resistance means that a fireproof coating needs to be applied to the part. Regardless, natural rubber remains a top choice for engine mounts.

2.Neoprene

While our natural rubber blend will handle the occasional oil/fuel exposure they are not designed for constant contact or submersion in oil or fuel. If this describes your application then Neoprene is the way to go. It is also a great choice for engine mounts because it is resistant to acid, ozone, flame, abrasion and water. Neoprene can also withstand an impressive range of common application temperatures.

For buyers who are looking for something similar to natural rubber but with better oil resistance than Neoprene is the perfect choice. It is not widely available for standard engine mounts, but it can be used in custom designed mounts. Neoprene engine mounts are sure to be reliable and provide long-lasting durability.

3. Silicone

One of the most important reasons to choose Silicone as your engine mount elastomer is its temperature resistance. This material is often used in baking goods and other high temperature environments, making it perfect for engine mounts that will be placed in a similar environment where radiant heat would consume other rubber materials.

The downside to using this material for engine mounts, is that it has low tear and abrasion resistance. Often, silicone is used on a case-by-case basis. In general, silicone is an excellent choice for many engine mount applications. If you aren’t sure whether or not silicone will work for what you need, talk to our team at RPM Industrial Rubber Parts. We use a high quality, in-depth analysis process with data points that you provide. This way, you know exactly what type of engine mount, including the material, that you need.

4. EPDM

EPDM is another great material to choose for engine mounts. It is not typically the first choice, but it is not completely ill-suited for the application. The best aspects of EPDM are its tear and abrasion resistance as well as its tensile strength.

The main reason why EPDM is not chosen often for engine mounting purposes is because it has low resistance to oils and acids. However, this is really only an issue if being used in an auto type application or similar. This material is best to use on a case-by-case basis rather than for all applications. Similar to Silicone, it is not commonly used in standard engine mounts but is still an excellent option.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Best Metal Materials for Engine Mounts

Engine mounts also utilize metal in the form of a bolt. It’s important to use high quality materials to ensure that the engine mounts stay in great shape. Here are some of the best metal materials for this part:

- Low Carbon Steel

- Stainless Steel

- Brass

- Aluminum

- Iron

Although the above materials are excellent choices, low carbon steel is often considered the best option for most engine mount environments.. This is because it is highly durable and retains integrity in all kinds of conditions. Aluminum is often considered a second best choice. It is lightweight and low cost, however a bit more prone to damage than stainless steel is. Talk to your manufacturer to find out the best metal material for the part that you need.

Custom Rubber Engine Mount Manufacturer

While there are many options for standard engine mounts, some OEMs choose to get custom made engine mounts. This offers a specifically designed part that perfectly fits the application. OEMs can choose the materials, design process, molding method, dimensions and more when they use a custom rubber manufacturer.

However, if you decide not to go the custom route, you can also choose from one of our many standard parts at RPM Industrial Rubber Parts. With so many options, it is often difficult to decide what you need. Our team uses an excellent analysis process to help find the perfect engine mount for your needs.

To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

The Complete Engine Mount Design Guide

Are you using the right engine mount for your system? Avoid the downfalls of choosing the wrong engine mount with our guide to engine mount design.