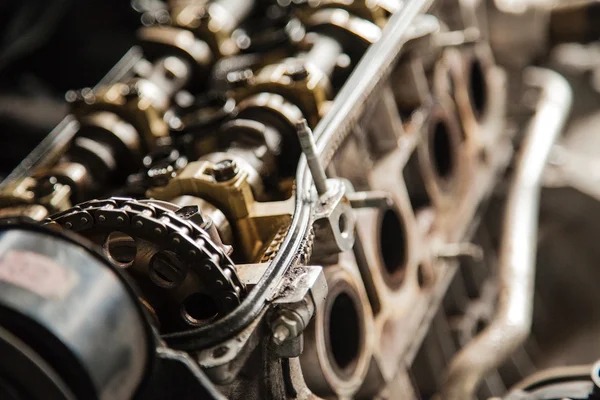

Engine and motor mounts are imperative to the long-lasting performance of a vehicle and other motor-reliant components. An engine mount’s ability to mitigate the harmful effects of noise and vibration can offer significant savings on repairs and replacements.

While there are plenty of standard engine mounts for purchase, necessary parts can often be unavailable or require a completely unique build.

This is where custom rubber engine mount services come in. At RPM Industrial Rubber Parts, we work side-by-side with OEMs to ensure they get the exact parts needed to meet whatever their engine mount needs may be.

Engine Mount Design Considerations

When it comes to designing engine mounts, RPM recommends several considerations when designing an engine or motor mount.

1. Industry and Application

Different vehicles require different engine or motor mounts. Not every motorized vehicle or equipment requires a standard engine mount. Some, such as off-highway vehicles, require specialized engine mounts dependent on the environments in which they operate. It’s important to consider the industry and application of the vehicle before designing the part.

For example, a bus or semi-truck will require a completely different mount than an off-highway vehicle such as forestry equipment. Understanding the application of the engine mount can inform later decisions such as materials, size, and shape. At RPM Industrial Rubber Parts, we take all of this and more into account to analyze what engine mount is best suited for your needs.

2. Type of Engine Mount

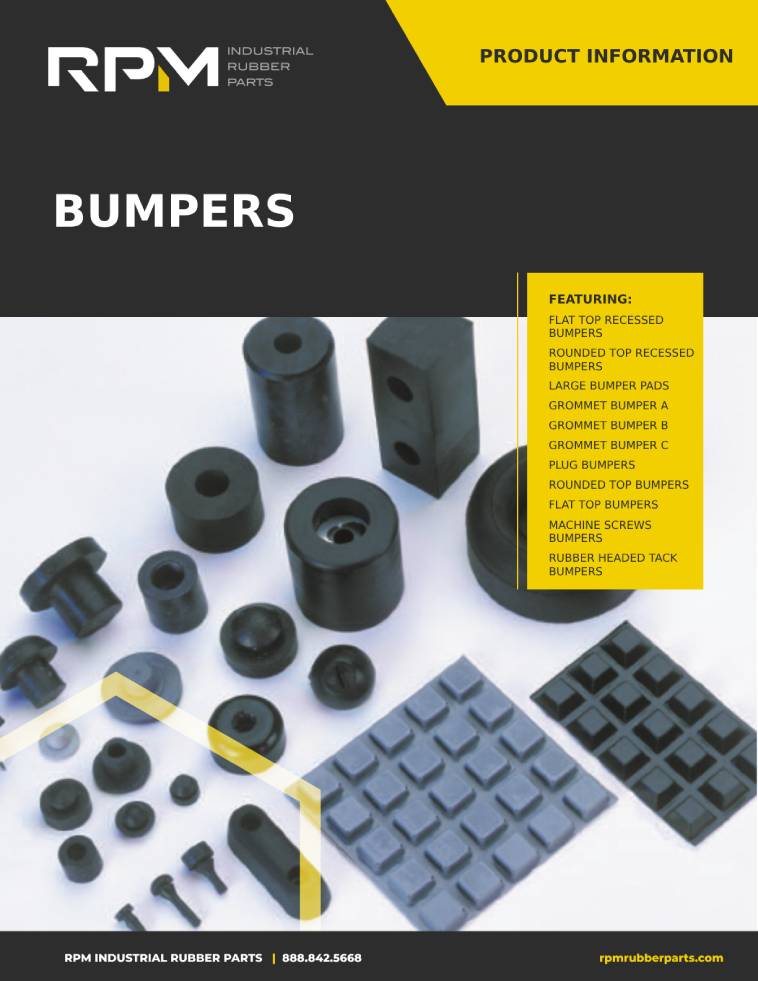

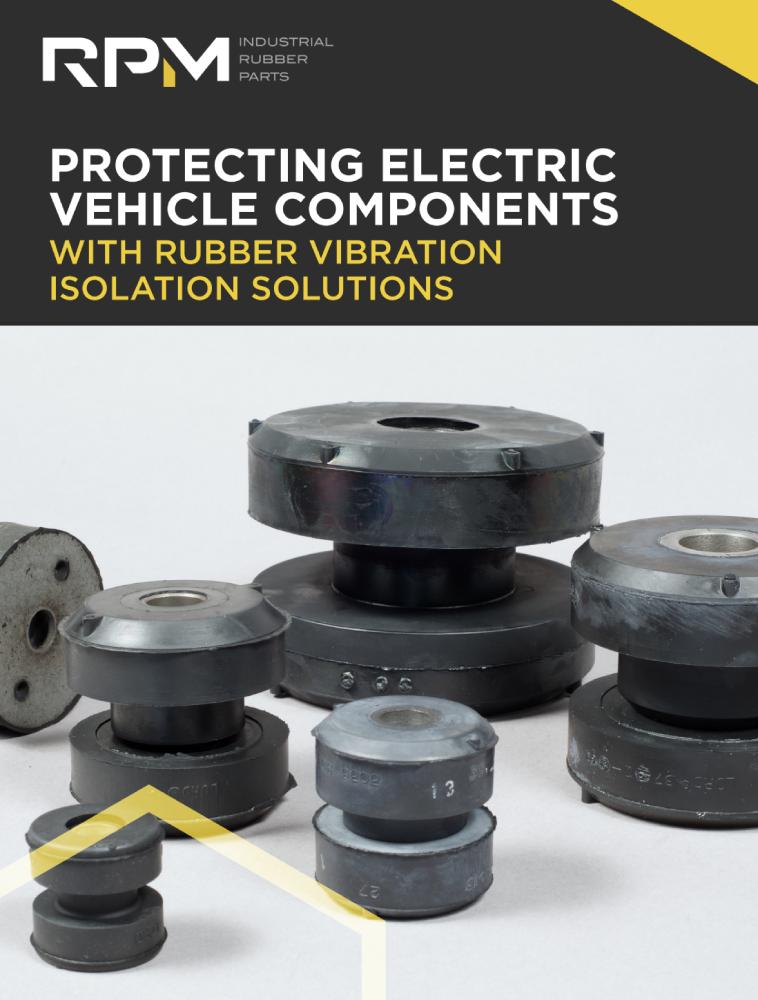

There are a few different kinds of engine mounts that OEMs may want to consider. These include:

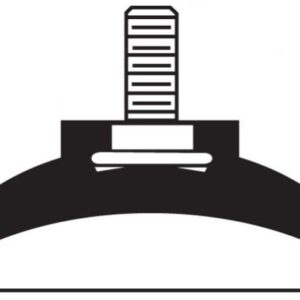

- Center bonded mount: these are single piece isolators that typically sit on a plant floor. Center bonded mounts are stationary and best for providing tensile support and suspension for various machinery engines.

- Conical mount: these high load-bearing mounts are excellent for vibration dampening and noise reduction. Conical mounts isolate shock, which provides a smoother experience for operators.

- Hydraulic engine mount: most commonly used for four or more cylinder vehicles, this engine mount contains hydraulic fluid to maintain flexibility and stability. The hydraulic fluid keeps the mount in better condition for a longer period of time.

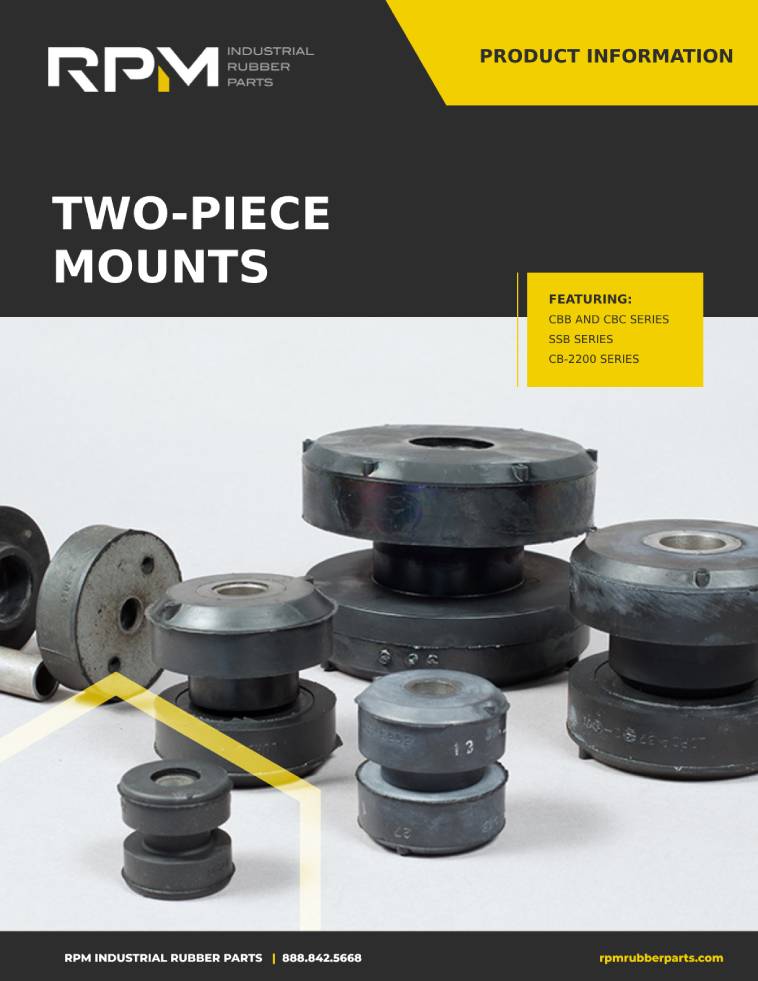

- Two-piece mount: these mounts are used in situations where dynamic forces come from both directions of the mount. Two-piece mounts are made of two rubber bases, rather than one, that work to absorb vibration and noise from both sides.

These are not the only types of engine mounts out there, which is why it is important to consider all of them. The type of engine mount required will typically depend on the application for the mount.

3. Design Process

There are two different design processes that can be used for custom rubber part design. The first is reverse engineering. This process is usually implemented when a part has been discontinued or changed. The design of the new engine mount will be based off of the older part. This is a great way to continue using the same part without having to worry about whether or not it will still be in stock.

The second design process is prototyping. This is most frequently used in situations where the new part is completely unique. Once the part has been designed and molded, the rubber manufacturer will send a prototype for approval. Then mass production of the part will begin. Manufacturers should choose the design process that works best for them.

This is typically only necessary if you are requesting a custom part. If you are searching for a standard part then you may want to focus on load bearing and vibration isolation capabilities rather than the design process.

4. Rubber and Metal Materials

The rubber and metal materials that are chosen for the engine mount will have a considerable effect on its reliability. Here are some of the best rubber materials used in engine mounts:

- Natural Rubber

- Neoprene

- Silicone

- EPDM

Natural rubber and neoprene are the most frequently used materials in engine mounts. This is because they have the best vibration absorption and resistance to vehicular conditions. Because engine mounts also contain metal parts, it is important to consider which metal to use:

- Stainless Steel

- Aluminum

- Steel

- Iron

- Brass

Steel is typically used in engine mounts due to its high durability. With all of the motion that engine mounts endure, it’s important that the selected metal is strong.

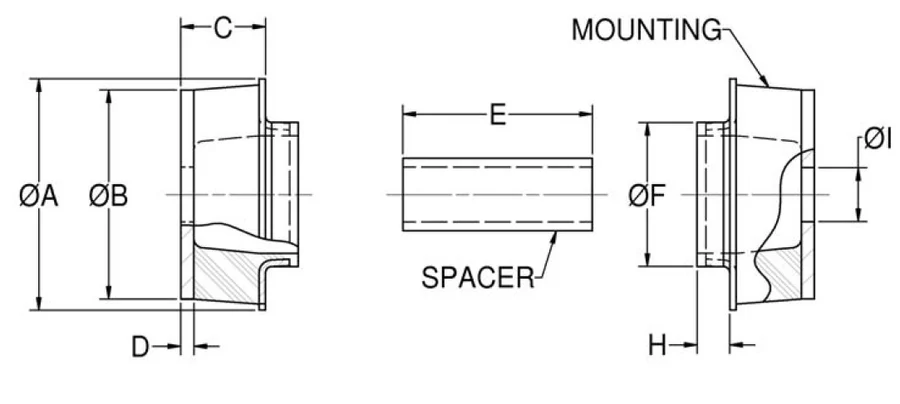

5. Dimensions and Aesthetics

The size, shape, and appearance of the engine mount is just as important as all of the above considerations. As explained, larger complex vehicles may require mounts that are expected to operate in harsh conditions. This may require multiple mounts in different orientations to isolate the disturbing frequencies. An engineer will be able to determine what the mount needs to look like.

When you talk to one of our engineers, they will ask you to fill out a form with all of the data points that we need to provide a proper analysis. This information will help us determine the dimensions and capabilities that your engine mount will require. In some cases, we may need to create an entirely custom engine mount and in other cases, you may be able to get one from our catalog.

In the case that you need a custom engine mount, keep in mind that they are typically not designed with aesthetics in mind. However, for companies that are looking to add extra flair or streamlined branding, engine mounts can be given protective coatings in different colors. Sometimes the rubber itself can even be molded in a different color. Not all manufacturers can do this and it is a custom process, so it’s important to talk to your manufacturer before requesting different colors and coatings.

6. Molding Process

There are three different molding processes for rubber engine mounts. Each one is used for specific purposes, so it’s important to consider your production needs. Here are the three processes:

- Injection molding: this is one of the most common molding processes. It utilizes an injector to push the polymer into the mold. Once it is cured, the mold will be removed. Injection rubber molding is best for complex parts that need to be made at high production volumes.

- Transfer molding: this is one of the least commonly used molding processes. Transfer molding starts with a solid rubber charge which is heated. Once heated, the liquid rubber will enter into the mold and cure. Transfer molding is a great option for complex parts that must be produced at a low volume.

- Compression molding: this method of molding utilizes a charge placed into a mold which is then compressed and heated. Once cured the part is removed from the mold. This type of molding is typically used for less complex, low volume parts.

Choosing a molding process will greatly depend on the complexity of the part and how many parts are needed.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Custom Rubber Engine Mounts

For high-quality custom rubber part services and a specialty in rubber mounts – you can trust RPM Industrial Rubber Parts.

Our experienced team of engineers and technicians is ready to help you solve your manufacturing woes. Whether you need a completely unique rubber part or you need us to recreate a part you already use. We have the tools and expertise needed. At RPM, we also carry standard parts ranging from tubing to vibration dampening.

To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

The Complete Engine Mount Design Guide

Are you using the right engine mount for your system?