Vibration theory provides an essential foundation for vibration isolators. At RPM, our engineers understand and create products based on tested ideas like this. Whether you are a casual customer, lead an OEM, or simply want to understand more, this treatment can enhance your knowledge.

Vibration Theory

Boiled down, vibration theory is simply this: the basis of every vibration system has three main components. These are:

Mass (M)

This could be a cab or a computer system. In this illustration, we’ll use the example of an engine system as the mass component.

Spring (K)

Consider a steel spring. If you compress it, it deflects some amount based on the applied force. There are two common types of springs that behave differently:

- Steel Springs: have a linear relationship between force and deflection

- Elastomeric Springs: may or may not have a linear relationship between force and deflection

Designed systems are most predictable with steel springs and linear force relationships.

Damper (c)

Damping is the property of the system to absorb energy. Consider a shock absorber on a car. If you hit a pothole, the car won’t bounce as much because the damper absorbs the energy. With elastomers in a vibration mount, damping is part of the elastomer. For every deflected amount, some are absorbed as a form of heat. The goal of that damping is to reduce the output for an isolator.

As damping increases, the output to the system decreases. When sizing mounts for a system, there is a necessary calculation that ensures this dynamic occurs.

Beyond these three primary aspects are some additional points of consideration.

Natural Frequency (Fn)

When force is applied to a spring, it will oscillate up and down. This is pretty consistent. The rate at which it oscillates is the natural frequency. Natural frequency can be expressed by the following equations (metric formula and in English units). The natural frequency determines what vibration mounts should be selected for optimal transmissibility.

Transmissibility

Transmissibility is a ratio of output over input. In any vibration isolation system, the goal is for the output to be as low as possible. That represents the most significant amount of isolation. On a chart, the peak may remain at the same magnitude. The goal is to be on the tail end of the curve, where we will attain the highest isolation level.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Types of Systems

The three categories above are considered when designing vibration isolator mounts. For many mounts, spring and damper are contained in the same mount. There are two types of systems that require analysis.

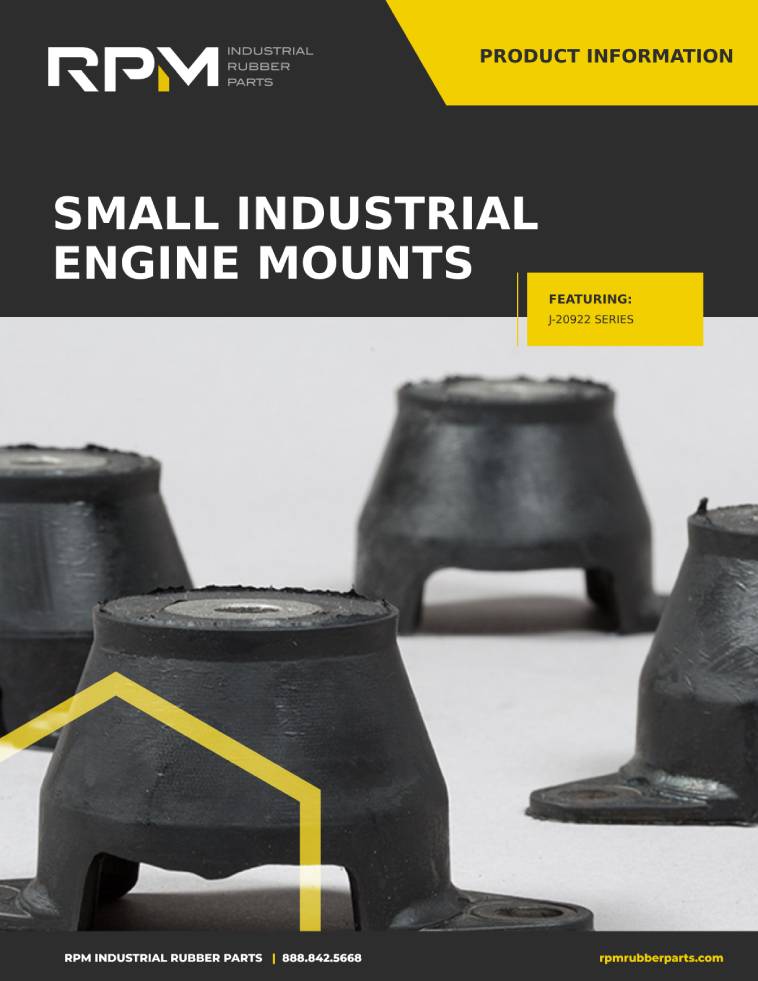

- The first is a Mass Excited system. Think of when the engine (mass) produces vibration and needs to be isolated from the vehicle’s frame. The vibration mounts protect the frame of the car from movement.

- The second is a Base Excited system. Consider an operator cab in the same vehicle. The goal would be to isolate all inputs (road, terrain, engine). In this scenario, the base itself must be isolated.

The Right Vibration Isolator

As with many things, the answer isn’t as simple as it may seem. Mount selection is a complex matter with a lot of variables. That’s part of why the RPM team provides consulting to provide the right recommendation for individual needs.

At the heart of the matter is a balance between motion control and vibration isolation.

RPM Vibration Isolators

RPM is an elite manufacturer of the best vibration isolators. RPM sells Parker Lord vibration isolators and other manufactured parts. If you are in the market for a manufactured rubber solution or need a consultation about the right vibration isolator for your application, give us a call at (888) 842-5668 or contact us.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.