- Vibration isolation in all directions.

- Noise attenuation.

- Easy installation because of one-piece design.

- Low-cost installation.

- Long service life.

- Consistent performance because of permanently bonded design.

- Shock protection in all directions provided by cushioned snubbing, no metal-to-metal bottoming.

- Standard sizes available from stock.

- Space-saving size.

- Captive installation after overload failure when recommended bolt, washer and nut are used.

- Accommodate English and Metric bolts.

CBA12-200-50 Center Bonded Mounts Cba 50 Series

Item #:

CBA12-200-50

/

Manufacturer:

Lord Corporation

Center Bonded Mounts isolate vibration, control shock and reduce noise due to structure borne vibrations. Available in a full range of rated load capacities and able to withstand shock loads of 10 g’s, these mounts effectively protect equipment and improve operator comfort. They are ideal for automotive, marine, railroad and industrial markets.Center Bonded Mounts provide…

Need a custom part similar to CBA12-200-50? Simply click to ‘Add to Quote Cart’ below and share your project information in the quote checkout. You can also give us a call at 888-842-5668.

Highlights

Spec Table

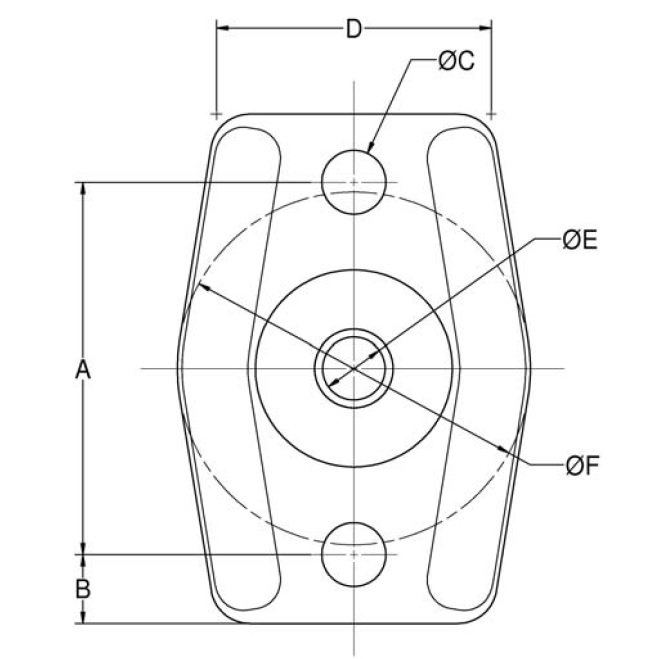

| A (Imperial) | 2.38 |

| Applicable Metal Bracket | Y-30266-5-1 |

| Application Engineering Assistance | Frequently, vibration isolation problems require a system engineering analysis. Lord has the computer capability, as well as specialized programs, for analyzing engine/ transmission combinations. The output from this analysis is a mounting proposal which optimizes performance over the complete range of operating speeds. This service is available to you upon request. |

| Axial Static Spring Rate (Imperial) | 2220 |

| Axial Static Spring Rate (Metric) | 389 |

| B (Imperial) | 0.44 |

| D (Imperial) | 1.75 |

| F (Imperial) | 2.25 |

| F (Metric) | 57.2 |

| I (Imperial) | 1.25 |

| I (Metric) | 31.8 |

| ID (Imperial) | 0.42 |

| ID (Metric) | 10.7 |

| J (Imperial) | 1.07 |

| J (Metric) | 27.2 |

| K (Imperial) | 1.25 |

| K (Metric) | 31.8 |

| Manufacturer | Lord Corporation |

| Material | Low Carbon Steel |

| Max Axial Static Load at Deflection (Imperial) | 200 at 0.09 |

| Max Axial Static Load Rating at Deflection (Imperial) | 200 at 0.09 |

| Max Axial Static Load Rating at Deflection (Metric) | 890 at 2.3 |

| Max Diameter (C) (Imperial) | 0.412 |

| Max Diameter (C) (Metric) | 10.5 |

| Max ID (E) (Imperial) | 10.4 |

| Max ID (E) (Metric) | 10.4 |

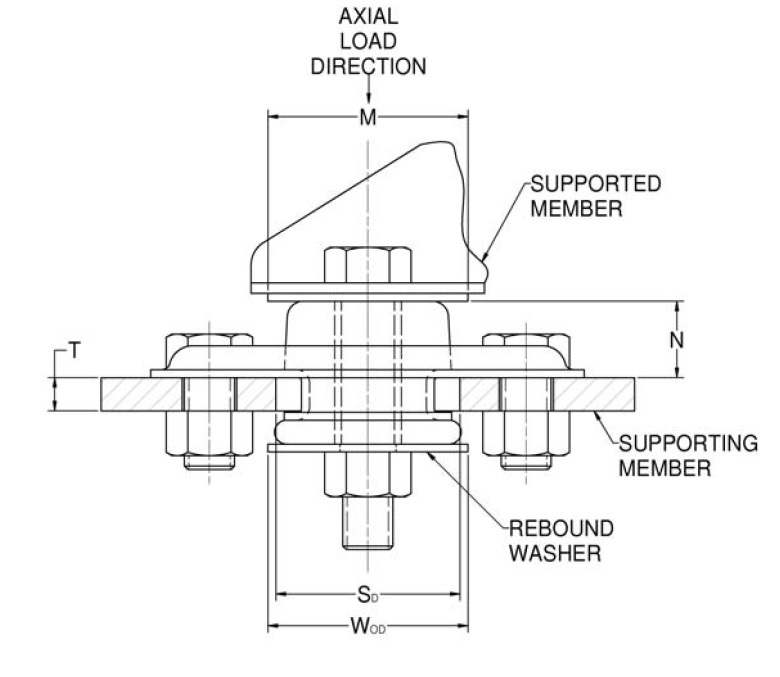

| Max T (Imperial) | 0.25 |

| Max T (Metric) | 6.4 |

| Min Diameter (C) (Imperial) | 0.404 |

| Min Diameter (C) (Metric) | 10.3 |

| Min ID (E) (Imperial) | 0.397 |

| Min ID (E) (Metric) | 10.1 |

| Min M (Imperial) | 1.5 |

| Min M (Metric) | 38.1 |

| Min T (Imperial) | 0.19 |

| Min T (Metric) | 4.8 |

| N (Imperial) | 0.57 |

| N (Metric) | 14.5 |

| OD (E) (Imperial) | 0.5 |

| Radial Static Spring Rate (Imperial) | 3000 |

| Radial Static Spring Rate (Metric) | 525 |

| Recommended Steel Washer | J-2049-58 |

| SD (Imperial) | 1.38 |

| SD (Metric) | 35.1 |

| Series | CBA-50 |

| Thickness (Imperial) | 0.12 |

| Thickness (Metric) | 3 |