Download Our Guide: RMA Extruded Tolerances

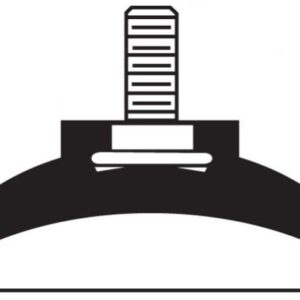

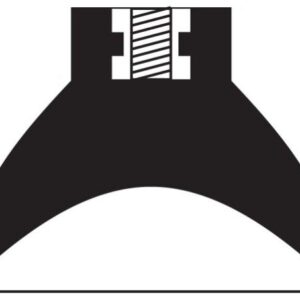

Extruded rubber components are manufactured with standardized dimensional tolerances to ensure consistency across various applications. These tolerances apply to key measurements like outside and inside diameters, wall thickness, width, and height, maintaining suitability for industrial use.

The Rubber Manufacturers Association (RMA) classifies tolerances based on factors such as material softness and post-curing needs. Softer materials or those requiring additional curing generally need looser tolerances, while dimensions over 100mm (3.94 inches) should be specified through agreement between supplier and user.

Though precise tolerances are crucial, cross-sectional dimensions below 1mm (0.04 inches) are typically impractical. Adhering to RMA standards helps balance accuracy with material properties, ensuring extruded rubber components meet functional and manufacturing requirements.