Off-road vehicles are valuable and technologically advanced. Industries as varied as agriculture and construction rely on off-highway heavy equipment and machines. The smallest factors can make a huge difference in productivity and longevity.

More industry leaders are making a strategic transition to autonomous vehicles or equipment models that use sensors to collect data and streamline operations. These parts, as well as engines and mechanical components, are subject to deterioration and damage from vibration. Only the best vibration isolators and effectively made sandwich mounts can mitigate these risks.

RPM Industrial Rubber Parts is a leading provider of sandwich mounts and other vibration-isolating parts to original equipment manufacturers (OEMs). Read on to learn how quality sandwich mounts and vibration-isolating rubber manufactured parts maximize efficiency and protect machines and operators.

From skillful analysis to manufacturing custom rubber parts, RPM is a trusted provider of mounts and parts for OEMs. To connect directly with our team of engineers and support personnel, contact us online.

Here are the topics covered in this design guide:

Sandwich Mounts: Form and Function

.webp?width=600&height=400&name=Flex%20Bolt%20Sandwich%20Mounts-2%20(1).webp)

Sandwich mounts are versatile parts that isolate vibration in vehicles, machinery, and equipment. They are made of high-quality materials to provide optimal vibration reduction. Materials are chosen based on specific tolerance criteria, but natural rubber is usually the right choice. Sandwich mounts are so called because the rubber part, typically shaped like an hourglass, is sandwiched between two metal plates. The metal plates are affixed to opposing surfaces. The rubber absorbs vibrations and reduces damage and noise.

Both elements of the sandwich mount are bonded together through an exacting rubber to metal bonding process. The bond is a crucial element, the strength of which should exceed that of the elastomer itself. In other words, the right bond for a sandwich mount would result in the rubber tearing before the bond itself. This makes it virtually impossible to break, ensuring that it protects the vehicle on which it is mounted.

Vibration Isolation Analysis

To understand what kind of sandwich mount is necessary for an application, we use vibration isolation theory. This formula takes into account the physics behind how isolation systems work and ultimately provides precise calculations for sandwich mount applications.

Vibration Isolation Theory

Finding the right vibration isolation mount requires data. It is inadvisable to flip open our catalog and choose a mount without doing some due diligence. If you want the best results possible, you need a sandwich mount that is the exact right combination of materials, form, and function.

Using the unique data points of your machine or equipment, vibration isolation theory is used to calculate the right parts for isolating vibration.

Calculating Vibration

There are three main components to vibration isolation theory: mass, spring, and damper. While a full understanding of each of these would require an engineering degree, the basics can be universally understood without too much effort.

MASS

This could be an engine, computer system or plate compactor. Think of ‘mass’ as the part that needs to be isolated. An important metric for vibration isolation (covered in a moment) is natural frequency (Fn), which is a function of mass (M) and spring rate (K). Mass must be recorded before further calculations can be made.

SPRING

When a spring is compressed, it bounces back in reaction to the applied force. Spring rate is the force needed to induce deflection of a spring. There are two types of springs: steel and elastomeric. Steel springs have a linear relationship between force and deflection, whereas elastomeric springs may or may not have a linear relationship — this depends on the load.

DAMPER

Damping is the capability of a system to absorb energy, such as vibration. Elastomers, such as rubber, have vibration-damping capabilities. This is why they are chosen as isolators. As vibration is deflected, the elastomer absorbs it.

The elastomer should reduce overall output, therefore isolating the system from the effects of vibration. This is why analysis is key to choosing the sandwich mount. Without understanding the proper capabilities and specifications, you may buy a sandwich mount that is incapable of absorbing the right amount of energy output.

NATURAL FREQUENCY Fn

The rate at which a spring bounces after force is applied, when the force is consistent, is known as the natural frequency. Transmissibility can be plotted against the frequency ratio. If a disturbing frequency is low, compared to a natural frequency, then the transmissibility is high. If the disturbing frequency is high, compared to a natural frequency, then the transmissibility is low. This is how natural frequency calculations are used to determine the spring rates optimal for vibration mounts.

Another variable these calculations account for circles back to the materials. Elastomeric mounts, when deflected, will convert some energy to heat. If no damping element is present, the system may oscillate even after input stops. Damping not only impacts transmissibility but causes oscillation to decay faster.

TRANSMISSIBILITY

Vibration-isolating systems are supposed to ensure that vibration output is as low as possible. Transmissibility is the ratio of output over input. When viewing a transmissibility chart, you’ll see the peak of output, near the top of the curve, and the lowest amount of output, near the low end of the curve. The goal is to be at the low end of the curve with little output.

SYSTEM TYPES

There are two systems that require analysis for designing and choosing sandwich mounts. These are:

1. Base excited system: using an operator cab as an example, the goal would be to limit all input. This could include the terrain, engine, and machinery function. In this situation, the base needs to be isolated from these external factors.

2. Mass excited system: consider an engine (mass) in a car. What would happen if the engine was not securely attached to the frame with rubber in between? This would most likely result in a damaged engine. A sandwich mount protects the vehicle, engine, and operator.

.jpeg?width=600&height=400&name=Rubber%20Metal%20Bond_Header-2%20(1).jpeg)

Mounting Strategies and Analysis Methodology

Analysis methodologies are key for creating mounting strategies. Without the correct information, a sandwich mount cannot provide vibration isolation. This analysis is used for many different systems to understand how a mount will perform.

Example: LORD Vibration Isolation Analysis for Engines

There are a few analysis methodologies that may be used for mounting strategies. Using the example of an engine application, here is a strategy developed by LORD.

LORD uses specialized vibration isolation analysis testing and software, called Harmony, to provide in-depth mounting solutions. By way of example, for vibration isolation in an engine, engineers work with the customer to collect the following data and build a model:

- We = Engine Weight (Wet, Including Accessories)

- Wt = Transmission Weight (Wet)

- He = Engine C.G. Height Above CSCL

- NI = Engine Speed – Idle

- NO = Engine Speed – Operating

- Number of Cylinders and Arrangement (I-6, 90° V-8, etc.)

When the model is complete, an engineering team will begin the analysis and determine the proper mounts necessary for the application. Both static and dynamic analyses will be performed. The static analysis is used for the engine weight and torque. The dynamic analysis is used for natural frequencies and engine disturbances.

In addition to operating range, accessory load, and performance requirements, an engineering team can determine the pitch, XYZ roll, and yaw analysis. This will provide the correct mount that corresponds to the vibration signature.

The mount recommendation will include styles, spring rates, and systems to provide operators with the best choices possible. Engineering experts will plot transmissibility to understand where each engine mount lies on the chart.

Want this kind of in-depth analysis? If you own or work for an OEM, RPM can work with you to analyze your machines, vehicles, or equipment and determine the right vibration-isolating sandwich mount. Contact us and learn more by reading The Complete Engine Mount Design Guide by RPM.

New Technology That Requires Vibration Isolation

Technology is driving innovation. OEMs have more tools than ever to enhance off-road vehicles and heavy machinery. This equipment is getting retooled and reworked, or reimagined entirely, to meet modern demands. In every industry, maintaining a competitive advantage relies on the ability of machines and vehicles to operate at peak performance.

Intricate dashboards, seamless software integrations, and even automation features make the difference between a company that thrives and one that falls behind. Invariably, the machines that make progress possible also require precise parts to increase the lifespan of equipment and protect profit margins. Sandwich mounts for vibration isolation are most certainly one of those essential parts.

Autonomous Vehicles

Self-driving cars are the flashy kin of an immensely practical and well-used set of new tech. Autonomous vehicles can follow predictable paths, deploy sequenced tasks, and gather invaluable data sets for operators. This makes off-road autonomous vehicles particularly useful in agriculture, forestry, mining, construction, and more.

Damage from noise, vibration, and harshness on these vehicles is similar in nature to human-operated versions. An additional factor is presented in fault detection, isolation, identification and recovery methods through perception sensors. Fault diagnosis systems are key to protecting autonomous off-road vehicles and mitigating future risk.

Any off-road autonomous vehicles that traverse rugged terrain require comprehensive feedback loops and reliable fault detection. This is achieved through the aforementioned sensors, which themselves must be well-protected. Any heavy-duty autonomous vehicle will have numerous sandwich mounts and other vibration-isolating parts.

Data-Gathering Sensors

Increasingly, off-road vehicles and heavy equipment are being equipped with high-tech sensors to monitor performance. Because they are delicate and calibrated devices, these sensors need to be isolated from vibration to ensure accuracy and performance.

Consider the following:

- In agricultural off-road vehicles, sensors may collect data on soil hydration or report planting or harvesting activities.

- In forestry, sensors may detect how many trees are harvested per hour.

Each of these sensors collects important data that optimizes efficiency. Without proper vibration isolation — often achieved by perfectly suited sandwich mounts — a sensor may be damaged, fail prematurely, or produce inaccurate results that skew data.

The precise calculations for every facet of the part itself and the mounting location are essential. Here is the information that is used to determine the correct mount for sensors:

- Supported load (mass of screen, box or sensor)

- Number of mounting points

- The disturbing frequency or input

- The desired output

This is the kind of information that an engineer will use to determine the right part for the vehicle or machine.

GPS (Global Positioning System)

Off-road GPS navigation systems have become more sophisticated. Now with stunning satellite images, touchscreen displays, preloaded topographic maps, and advanced connectivity, these are more valuable and important for navigating terrain during off-road jobs. Installed in everything from ATVs to logging machines to mining equipment, GPSs keep teams on the map at all times, ensuring precise work in specific locations.

GPS anti-vibration parts should effectively protect the equipment itself from shock. This may be done by rubber sandwich mounts installed in the cab, near the dashboard, at strategic joints or in moving parts of the vehicle. Achieving vibration isolation for the entire machine should have the added benefit of preserving the longevity of the precision equipment mounted within.

.jpeg?width=600&height=400&name=drive-863123%20resize%20(1).jpeg)

Cameras

While sensors, computers, and screens all require vibration isolation to function well, cameras require an elite level of protection. This is because vibration would not only cause damage but would inhibit the camera from capturing required images. Vibration is noticeable to operators through sound and sight. When the latter is disrupted, camera captures are inferior. The bottom line is that if a vehicle is moving and shaking, a camera that is meant to capture photographic evidence or records of terrain or work will be unable to deliver the desired result.

Vibration isolators for cameras are a well-established product used in a vast array of industries. Rigs, wire mounts, and entire isolator systems may be built into or around a camera. For film or even surveillance equipment, these mounts may be affixed with magnets, clamps, or even suction cups. When a camera is installed in an off-road vehicle, it of course requires masterful vibration isolation of the entire machine to achieve desired performance.

Mechanical Systems

Integral to the proper function of off-road vehicles, mechanical systems themselves may be at risk if they lack proper vibration isolation. Sandwich mounts that address concerns of mechanical resonance can be installed. Abnormal vibrations are often not immediately apparent and can occur over time from imbalances, misalignment, loose connections, or simple wear and tear.

Whether in heavy machinery or industrial applications, safety and productivity issues loom large. Rubber engine mounts and sandwich mounts are the most popular choice to protect mechanical systems. The key is buying high-quality sandwich mounts that are made of superior materials, manufactured with precision, and have the right specifications to fit the application.

Industries with Vehicles That Require Sandwich Mounts

There are ongoing innovations in off-road vehicles themselves that require new methods of vibration isolation through mounts. Innovators are always looking for new ways to refine a machine’s function to minimize waste and maximize productivity. Some industries are clearly leading the way in these efforts.

Here are some examples typified by RPM’s OEM client base:

Forestry

Autonomous forestry equipment and traditional forestry vehicles alike benefit from sandwich mounts for vibration isolation. Off-road forestry vehicles have the typical components: cab, engine, dashboard, sensors, cameras, GPS, etc. What our OEM partners often have to consider is that every attachment added to a forestry vehicle changes the dynamic and vibration of that vehicle.

Forestry equipment includes machines for tree harvesting and severe duty off-road equipment like this:

- Processors

- Harvester

- Delimbers

- Forwarders

- Yarders

- Horizontal grinders

- Wood chippers

- Log trailers

- Mulchers

- Log loaders

- Skidders

- Log trucks

- Feller bunchers

- Tub grinders

The goal of fleets of forestry vehicles and forestry systems is to lower the cost per ton while delivering more processed wood.

Often, attachments are interchanged even through the course of an on-site task or project. It’s important that OEMs and companies that operate forestry vehicles and machines work with engineers to calculate the right number of sandwich mounts and the right placement of sandwich mounts for holistic vibration isolation. As these types of vehicles evolve, they are coming to include more lights, sensors, radars, and systems that all require precise care and protection.

The risk of early failure due to inferior sandwich mounts or other parts is high. For some forestry operations, it could amount to hundreds of thousands of dollars a day. This immense cost is perhaps rivaled only by the cost of downtime in mining.

Mining

Mining is precision work that utilizes ultra-specialized and heavy-duty machines. Hard rock products for surface mining and underground mining use advanced technology to assess sites and bore beneath the surface of the earth. Lighting, cameras, radars, and sensors are incredibly important to mining operations.

Even if you are not an OEM of mining equipment, you can imagine the incredible vibration that must be minimized. Machines that are taking on the impact of hard rock mining and more must be sufficiently protected through masterful damping by sandwich mounts.

Surface mining equipment includes things like the following:

- Draglines

- Electric rope shovels

- Blasthole drills

- Hybrid shovels

- Surface crushing equipment

- Surface conveying equipment

- Wheel loaders

Underground vehicles and underground mining equipment are equally at risk and also require superior sandwich mounts and vibration isolating parts. Machines in this category include:

- Hard rock equipment

- Tunneling equipment

- Underground crushing equipment

- Underground conveying equipment

- Ground support vehicles

- Ore flow facilitation vehicles

- Drills

- Utility vehicles

Quarrying and hard rock mining have their own unique off-road vehicles. The types of machinery in the quarry industry that require vibration isolators include:

- Stripping and drilling equipment

- Wheel loaders

- Off-highway trucks (or rock trucks)

- Crushing equipment

Quarrying machines and hard rock mining machines are some of the toughest ever created. They have to sustain major environmental impacts and have enormous haul capacities. Because many off-road quarrying vehicles are often used to convey collected materials, they often have arms and other accessories which complicate the role of vibration isolators. To install the right part that’s up to the task, reach out to RPM at (888) 842-5668.

.jpeg?width=600&height=400&name=mining-excavator-resize%20(1).jpeg)

Agriculture

Agriculture and food sectors in the U.S. contribute over $1 trillion to the U.S. gross domestic product. America’s farms account for over $136 billion of that. Harvesting performance is key to keeping family farms and corporate farms alive and functioning. Ag is a great industry for automated vehicles and one that has used them for a long time.

Often functioning on flat land, without many terrain surprises, and on predictable courses, off-road agricultural vehicles can get repetitive tasks done without a human operator. As long as the right combination of automation software, cameras, radars, and sensors is installed and protected from damage, a meaningful cycle of task completion and data collection can create a positive workflow that maximizes agriculture productivity.

A lot of crop-related equipment types benefit from sandwich mounts:

- Harvesting equipment

- Foraging equipment

- Seeding and planting equipment

- Tillers

- Sprayers

- Shredders and cutters

- Combines

- Plows

- Spreaders

- Balers

Some of these vehicles have a drum or roller on the front, which may be used for tilling, seeding, or even harvesting. This rotating drum experiences a huge shock behind the front wheels and has an impact bumper that prevents it from going further. Crop-related equipment like this usually has sandwich mounts installed around the drum, the cab, the dash, and more.

Oil and Gas

OEMs in the U.S. and Canada supply to companies that perform directional drilling to harvest oil or gas. There are strict safety protocols in place for operators in these industries. Drills represent a unique challenge in terms of vibration, as the multidirectional nature of a spring significantly impacts mount selection. Oil and gas require numerous specialized off-road and heavy-duty vehicles, including:

- Drills

- Drilling rigs

- Augers

- Degassers

- Shale shakers

- Sand pumps (Fracing Vehicles)

- Cementers

- Coil Tubing Vehicles

Most of these have sensors and diesel engines and are accompanied on a job site by trailers, generators, trucks, tanks, drums, and other ground support vehicles.

RPM serves many clients in the fracking industry. Fracking requires powerful drills that open a path for the injection of a high-pressure water mixture. Directed into this rock, this causes a release of the gas inside, which then flows up through a well. Some of the equipment that performs these tasks includes:

- Fracking vehicles

- Fracking pumps

- Blenders

Fracking equipment is heavy-duty, off-road, and able to sustain high-power, high-energy situations day in and day out. Add in the stress of the environmental factors and operators have to be incredibly careful how they install sandwich mounts and other parts that protect this kind of equipment.

Part of the reason OEMs choose RPM for fracking and other oil and gas or mining equipment is because we provide a consultative approach. As a trusted partner, we will work with you to do a thorough analysis and ensure that you are installing long-lasting parts that support operations.

Utility Forklifts

Used in numerous industries, utility forklifts serve a wide variety of purposes. In off-road vehicles or on job sites, the equilibrium and stability of the forklift is a huge priority. While that should be achieved by an OEM during manufacturing, the additional vibration isolation is of similar importance. When chosen and installed correctly, sandwich mounts for utility forklifts will ensure the safety of operators and long life of this useful machine.

There are a few types of utility forklifts, which include:

- Side loader

- Telehandler

- Industrial forklift

- Warehouse forklift

- Pallet jack

- Counterbalance forklift

In some cases, a rough terrain forklift may be the right choice. These vehicles go over rugged terrain carrying palettes of material and may be seen on construction sites and in other places. The safety of the load, as well as the vehicle itself, is ensured through vibration isolation.

Parts and Mounts for Off-Road Vehicles

It should be crystal clear by now that selecting the right sandwich mount for vibration isolation of off-road vehicles is a high priority. The OEMs we work with attest to the fact that vehicles, machinery, and equipment last longer and perform better when the right sandwich mount is selected and installed.

Not all sandwich mounts are created equally. Some are manufactured with inferior parts. The cost-saving of a low-quality sandwich mount is quickly erased by its low performance and short lifespan. What’s more, installing a bad sandwich mount can have catastrophic results in terms of early vehicle failure or operator harm.

RPM is committed to providing high-quality parts for our clients, many of whom work with leading OEMs. We understand what is at stake and have the expertise to select the right part for you. Because they are considered some of the best quality, RPM is proud to provide OEMs and other clients with many LORD sandwich mounts and other LORD products. If you are looking for sandwich mounts, here are some from our catalog that can get you started:

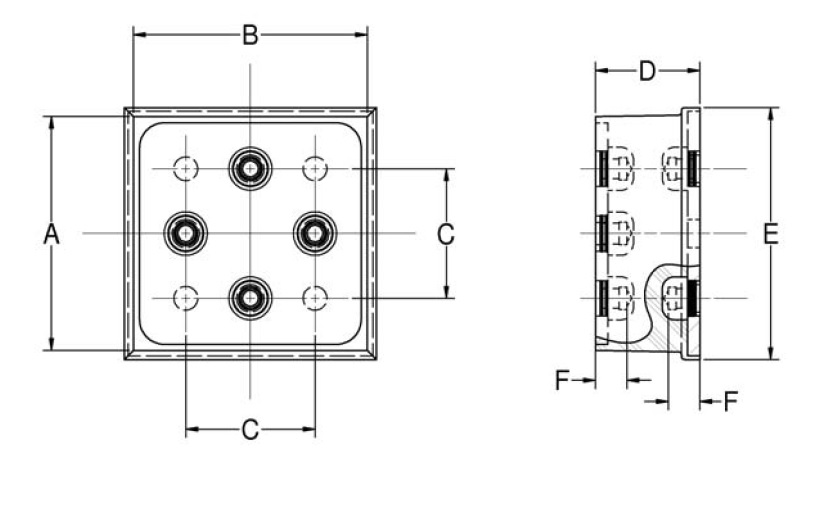

J-14056-4

J-14056-4 is a LORD large shear mount made of natural rubber. This sandwich mount has a 3670 lbs compression static load, 770 lbs shear static load and 5100 lbs compression spring rate.

SMA090-0900-1

SMA090-0900-1 is another large LORD shear mount made of natural rubber. This sandwich mount has a 7600 lbs compression static load, 900 lbs shear static load and 10500 lbs compression spring rate.

SMA090-0900-3

SMA090-0900-3 is a LORD sandwich mount made of natural rubber. This mount has a 7600 lbs compression static load, 900 lbs shear static load and 10500 lbs compression spring rate.

SMA095-1200-1

SMA095-1200-1 is one of our large shear mounts, also made by LORD. It also has natural rubber and a 5800 lbs compression static load, 1200 lbs shear static load and 5800 lbs compression spring rate.

SMA095-1200-3

SMA095-1200-3 is a large shear mount with natural rubber, made by LORD. It has a 5800 lbs compression static load, 1200 lbs shear static load and 5800 lbs compression spring rate.

As you can see from these few recommendations, the difference between static load, shear static load, spring rate, and other vital stats is significant even between similar sandwich mount products. These are not the exhaustive specifications of each product, the detail of which is vital to know before you buy or install a sandwich mount. With the link beneath each product recommendation, you can read more about the specifications of the part.

.jpeg?width=600&height=400&name=large%20sheer%20mounts-resize%20(1).jpeg)

RPM: Buy Sandwich Mounts for Off-Road Vehicles

If you want to buy a sandwich mount online, we strongly suggest that you first reach out to our sales department. Especially if you are an OEM looking for bulk sandwich mounts or replacement sandwich mounts, we can perform the right analysis to achieve optimal vibration isolation. Contact us online or call our sales department to learn more: (888) 842-5668.