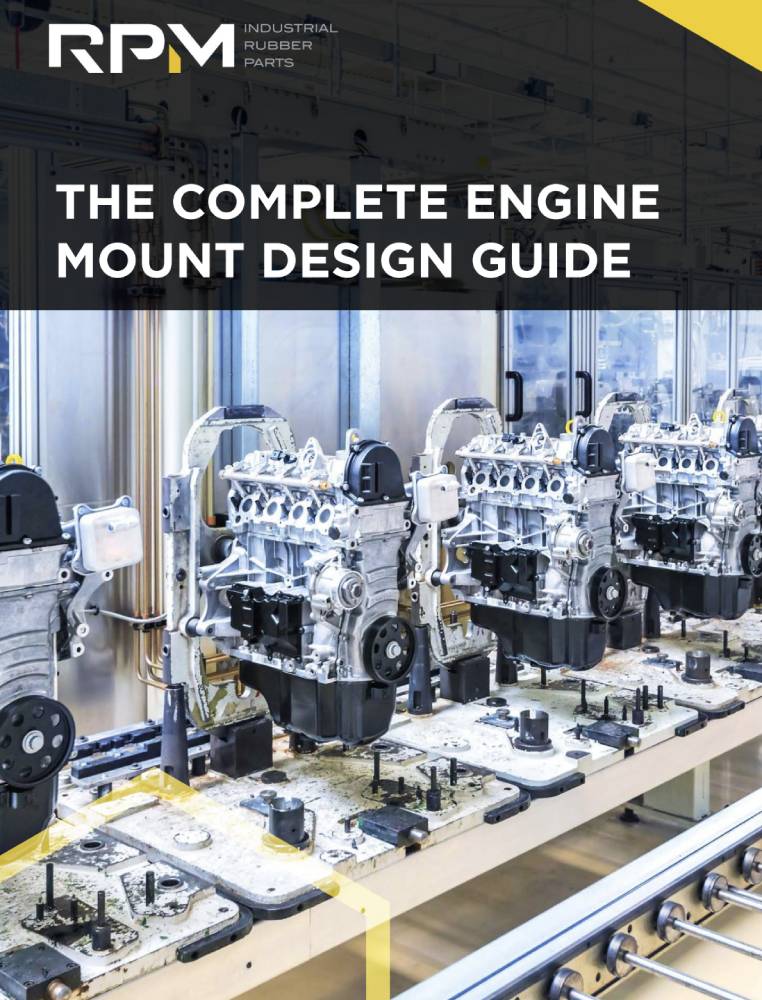

Download Our Guide

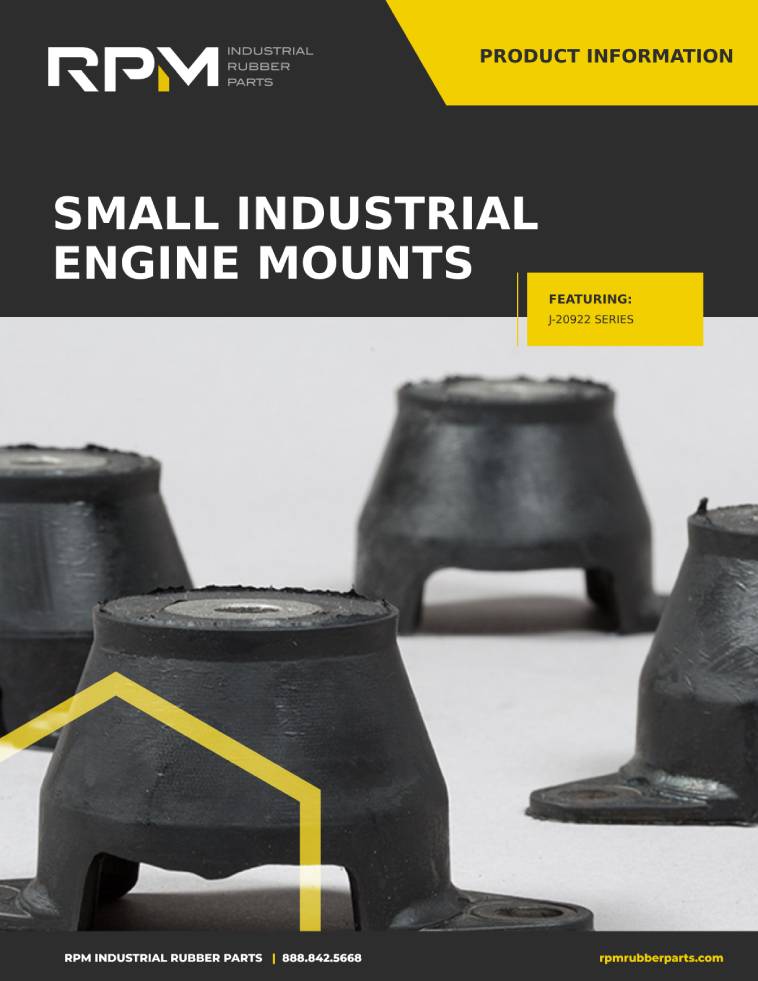

Engine mounts are essential to the proper functioning of any motorized vehicle. From automobiles to airplanes to industrial equipment, engine mounts make equipment run quieter and last longer. Also known as motor mounts or isolators, these parts ensure that the engine stays in place and provides the important function of absorbing energy from the engine being transferred to the rest of the system. In specialty equipment and vehicles, traditional engine mounts don’t always work or are selected incorrectly, which can lead to the system actually amplifying the vibration rather than reducing it. This is why many manufacturers turn to customizable engine mount design and analysis for their needs.

When designing rubber engine mounts, there are a variety of aspects to consider such as materials, cost, and function. There are all kinds of engine mounts that all come in different sizes and types, selecting the right one can be a daunting process. However, through customization processes and analysis, the engine mount can be designed to meet certain specifications and optimize performance of the system.

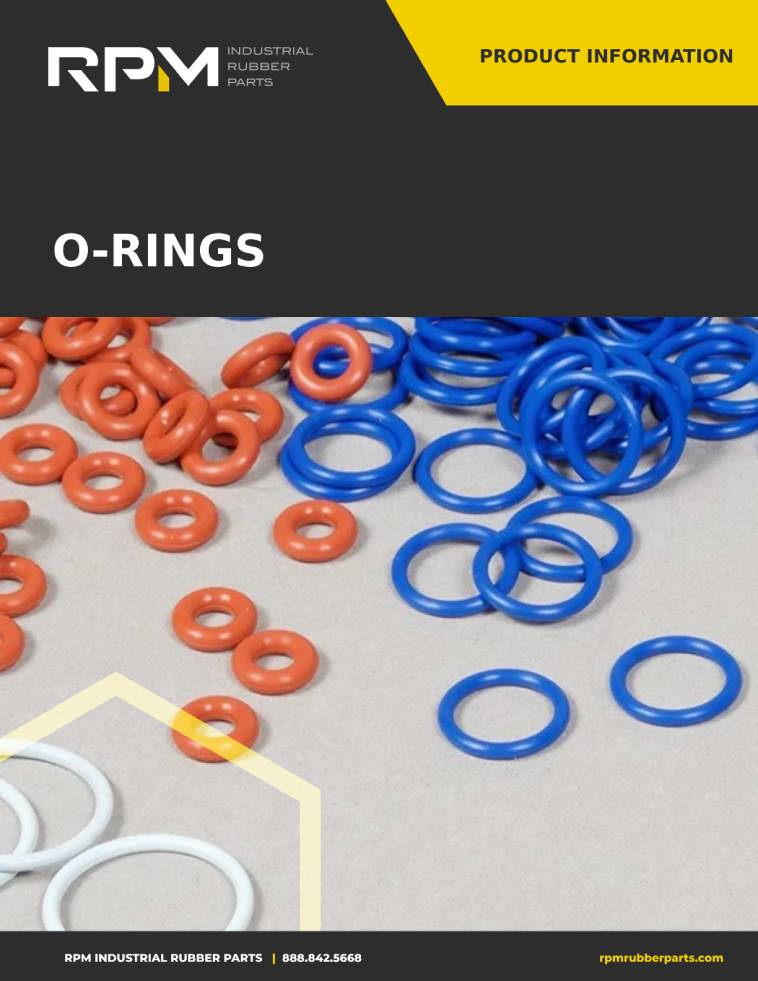

At RPM Industrial Rubber Parts, we help clients design the part that they are looking for. We have expert engineers and helpful staff who are ready to walk you step-by-step through the analysis, design, and manufacturing process. We have a wide variety of standard rubber isolation parts with the ability to produce custom components for special and unique applications.