Download Our Guide: Molded Rubber Tolerances

Molded rubber components are manufactured with specific dimensional tolerances to ensure consistency and reliability in various applications. These tolerances, measured in inches, are classified based on precision levels to meet different design and performance requirements.

The Rubber Manufacturers Association (RMA) defines four tolerance classes: high precision (Class A, DWG Designation A) for applications requiring the tightest tolerances, precision (Class 1, DWG Designation A1) for demanding but slightly less strict specifications, commercial (Class 2, DWG Designation A2) for standard industrial use, and non-critical (Class 3, DWG Designation A3) for applications where dimensional variation is acceptable.

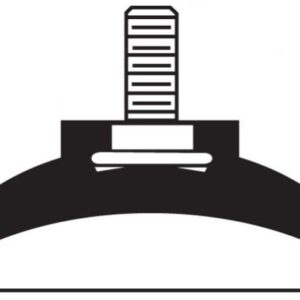

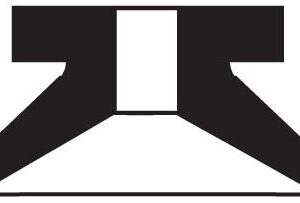

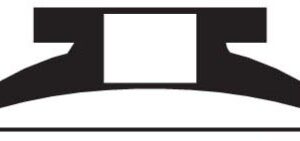

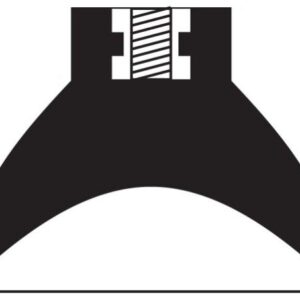

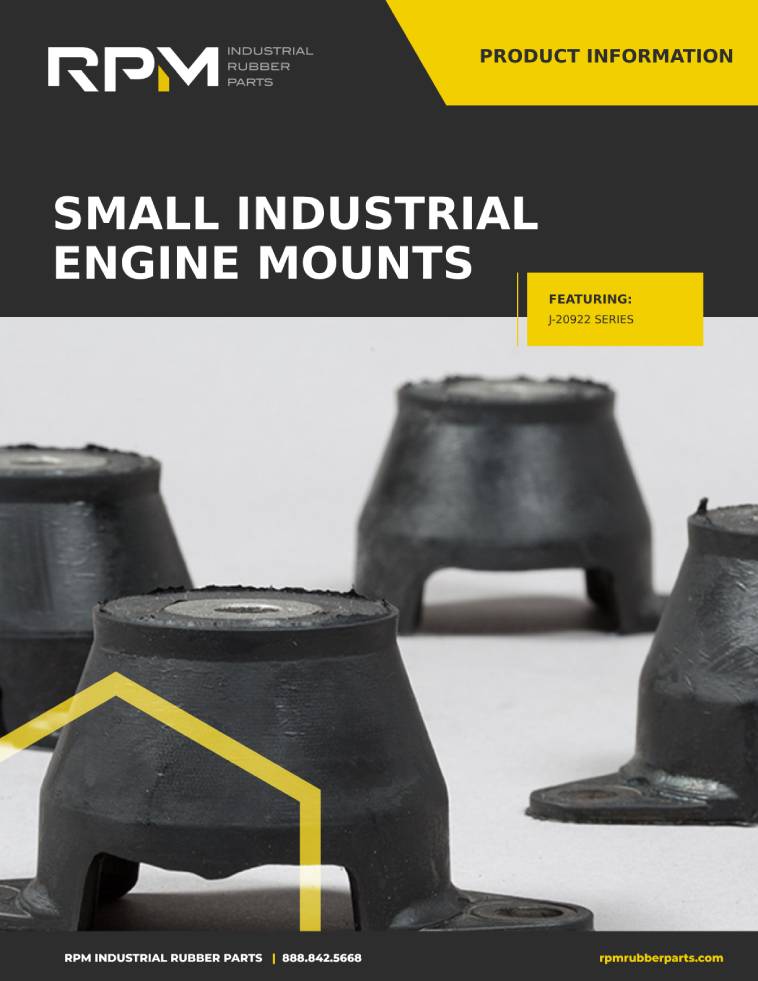

These mounts are particularly well-suited for low mounting locations and support load ratings between 120 and 300 pounds, making them ideal for a variety of engine sizes and application types.