Download Our Guide

In today’s fast-paced industrial landscape, the role of expertly crafted rubber products cannot be overstated. These components are the unsung heroes in isolating vibrations, a critical factor in safeguarding both sophisticated machinery and the invaluable operators behind them. This protective measure is indispensable across leading sectors where the machinery’s complexity and the demand for precision run high.

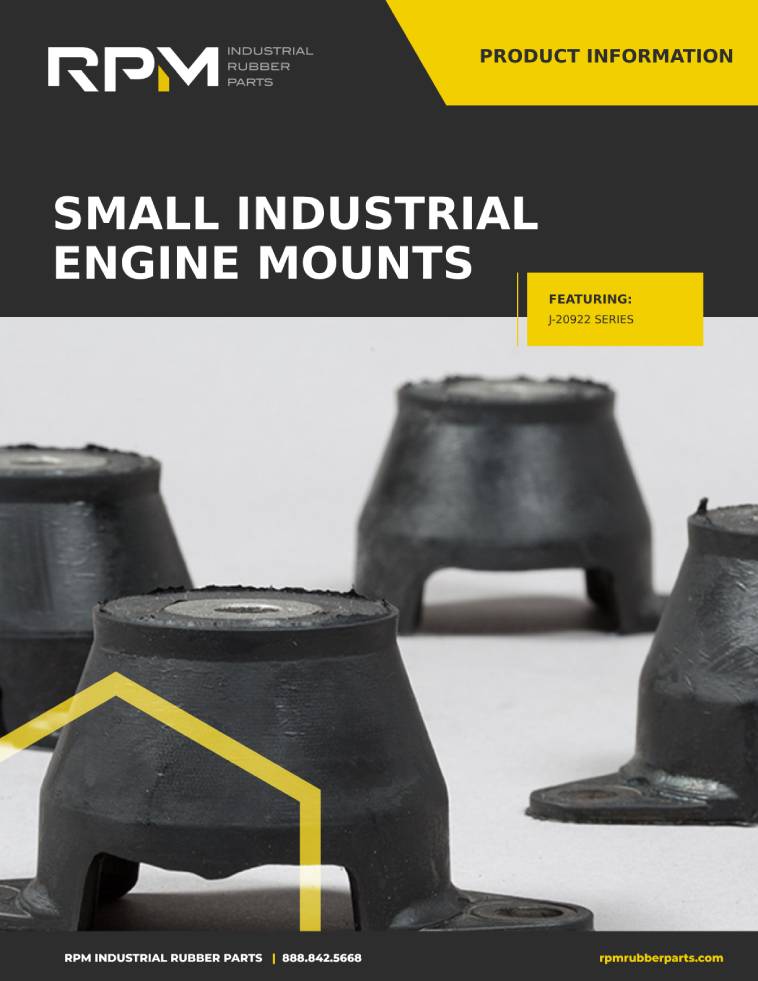

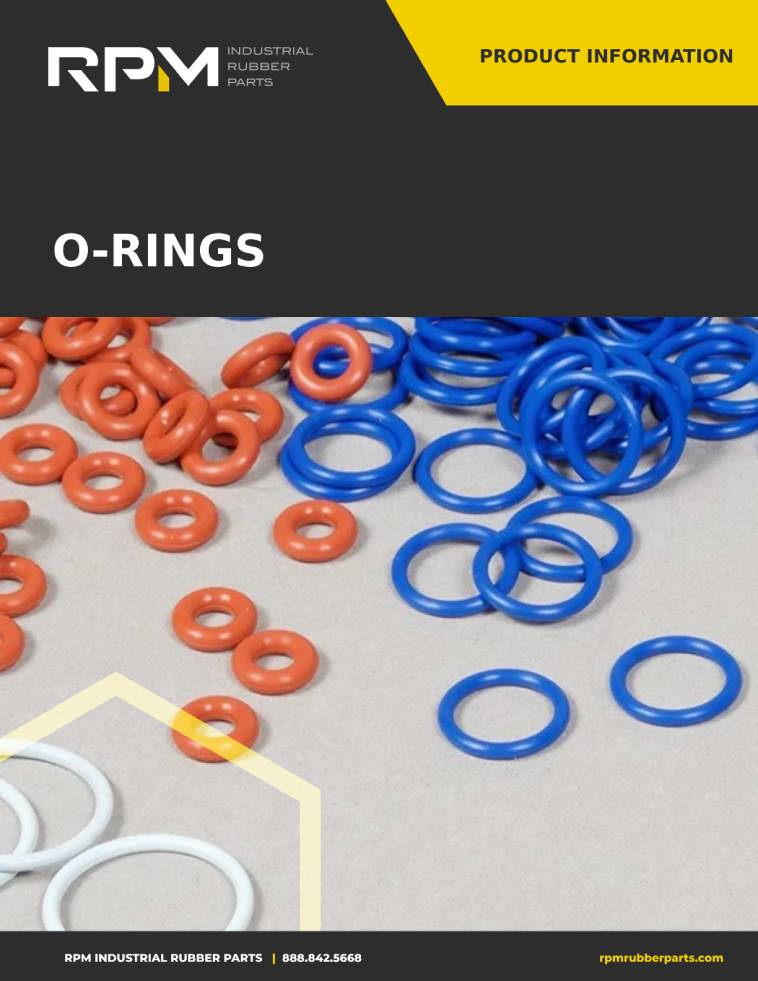

Downtime due to equipment failure is more than an operational hiccup; it’s a significant financial setback stemming from lost productivity and escalated maintenance costs. Often, the root cause is traced back to inadequate vibration isolation. Excessive vibration not only accelerates the wear and tear of internal components but also compromises the machinery’s overall performance and lifespan. Implementing high-quality rubber mounts, bearings, and suspension systems is crucial in mitigating these issues, thereby enhancing equipment durability and operator comfort.

Understanding the intricate requirements of specialized machinery, RPM Rubber Parts stands at the forefront of rubber manufacturing. Our expertise lies in designing and delivering rubber components that meet the exacting needs of your applications. Let us navigate you through our comprehensive solutions, ensuring your equipment operates at its peak while minimizing discomfort and downtime.