Battery Isolation In Electric Vehicle Applications

Designing for the Future

Off-highway electric vehicles are vehicles designed to operate in rugged, unpaved, or uneven terrain, and are powered by electric motors. These vehicles are used in a wide range of industries, including construction, mining, agriculture, and forestry, among others.

Off-highway electric vehicles have several advantages over traditional diesel-powered vehicles, including lower operating costs, reduced emissions, and quieter operation. They also have the potential to improve safety and reduce maintenance requirements.

Some examples of off-highway electric vehicles include electric excavators, bulldozers, loaders, tractors, and harvesters. These vehicles typically use large, high-capacity batteries to power their electric motors, and may also use regenerative braking to recharge their batteries during operation.

As technology continues to advance, it is likely that we will see even more innovation and development in the field of off-highway electric vehicles, as companies seek to reduce their carbon footprint and meet the growing demand for sustainable transportation solutions.

Speak to an Engineer

Let us help solve your EV design challenges.

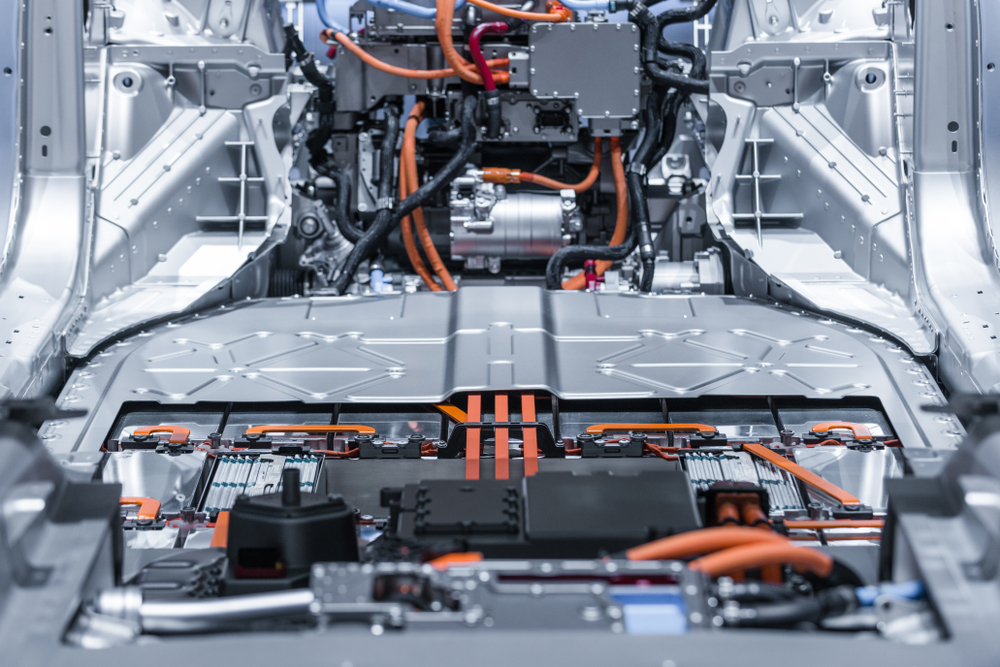

Battery Isolation in Off-highway Design

Battery isolation in off-highway electric vehicles is an important safety feature that helps to prevent electrical shock and reduce the risk of fires or explosions. It involves separating the high-voltage battery from the rest of the vehicle's electrical system, typically through the use of high-voltage relays or contactors.

The battery isolation system is designed to activate automatically in the event of an accident or other safety-related incident. For example, if the vehicle detects a sudden impact or a short circuit in the electrical system, the battery isolation system will immediately disconnect the battery from the rest of the vehicle, cutting off the flow of electricity and preventing potential damage or injury.

In addition to safety concerns, battery isolation can also help to extend the life of the battery by preventing overcharging or deep discharge, which can lead to premature failure.

Overall, battery isolation is a critical safety feature in off-highway electric vehicles, and is essential for protecting both the vehicle and its occupants in the event of an accident or other safety-related incident.

Vibration Isolation in Off-highway Design

Vibration isolation is an important design consideration in electric vehicles, as it can affect both the comfort of the passengers and the performance and longevity of the vehicle's components. Electric vehicles have electric motors that generate high torque at low speeds, and this can lead to increased vibrations and noise levels, especially in the cabin.

To address this, manufacturers may incorporate various vibration isolation techniques in the design of electric vehicles. One approach is to use special mountings and damping materials in the suspension system and other components to absorb and isolate vibrations. This can help to improve ride quality and reduce noise levels.

Another approach is to use active noise and vibration cancellation technology, which uses sensors and speakers to detect and counteract vibrations and noise in real-time. This can be particularly effective in electric vehicles, as the electric drivetrain generates a relatively constant level of noise and vibration that can be easier to predict and cancel out.

Vibration isolation is also important for protecting sensitive electronic components in the vehicle, such as the battery and power electronics. Vibrations can cause mechanical stress and potentially lead to premature failure, so isolating these components can help to ensure reliable operation over the lifetime of the vehicle.

Overall, vibration isolation is an important consideration in the design of electric vehicles, and manufacturers may use a variety of techniques to minimize vibrations and noise levels and ensure a comfortable and reliable driving experience.

OHEV Video Gallery

Hear From Our Experts...

We sat down with RPM’s Vice President, Mike McNeil, and asked him some questions to learn firsthand what he’s been hearing from customers and interested parties looking towards the future of the OHEV space.

Explore our video gallery to learn more about both the present and future of OHEV development.

Interesting Reading on the Off-highway Electric Vehicles

The Battery Electric Vehicle Trend Moves Off-highway

by Wallenius Wilhelmsen

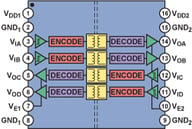

Isolation in Electric Vehicle Systems Quick Reference (PDF)

by Skyworks Inc

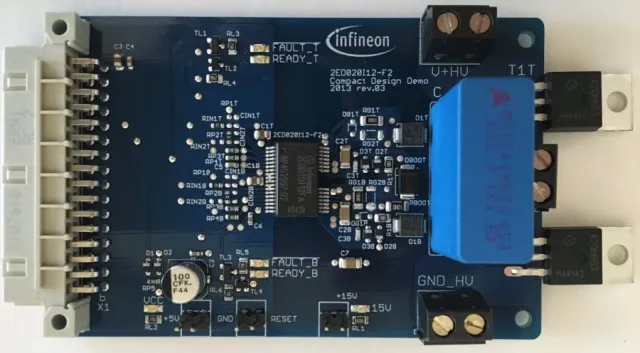

Isolation in High-Voltage Battery Monitoring for Transportation Applications

by Analog.com

Galvanic Isolation in Electric and Hybrid Vehicle Applications

by EE Times (EU)

Read Article HereWhy Partner with RPM?

Material certifications

Since we serve a variety of industries, the majority of our products are compliant with specific industry requirements, such as the Restriction of Hazardous Substances Directive (RoHS) and the automotive industry’s Production Part Approval Process. Written documentation and certifications are available on request.

Product samples

For standard in-stock parts, we are happy to provide a limited number of free samples to ensure you find the best part. Where we do not carry the needed part, we offer an economical prototype and a small run option.

Payment methods

We accept payments by American Express, MasterCard, and Visa. You can also contact our customer service department to set up credit terms.

Minimum orders

For anything we have in stock, the minimum is $75 per order. Contact our customer service representatives for minimums associated with custom products.

Shipping

We have warehouses in both Ontario, Canada, and New York, USA, so that your order can be shipped domestically. This prevents the delay and expense of cross-border shipping, giving you peace of mind that your order will arrive when you need it. We also ship internationally.