Download Our Guide: Center Bonded Mounts

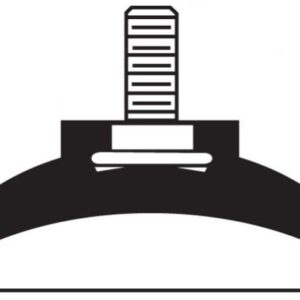

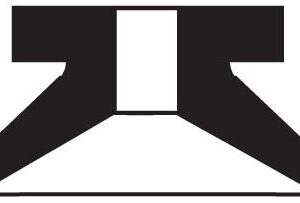

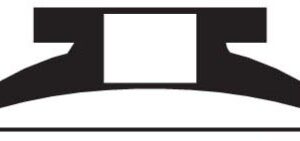

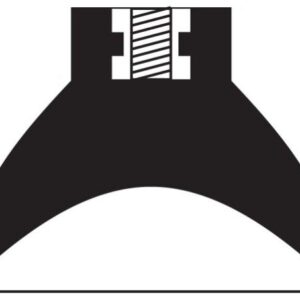

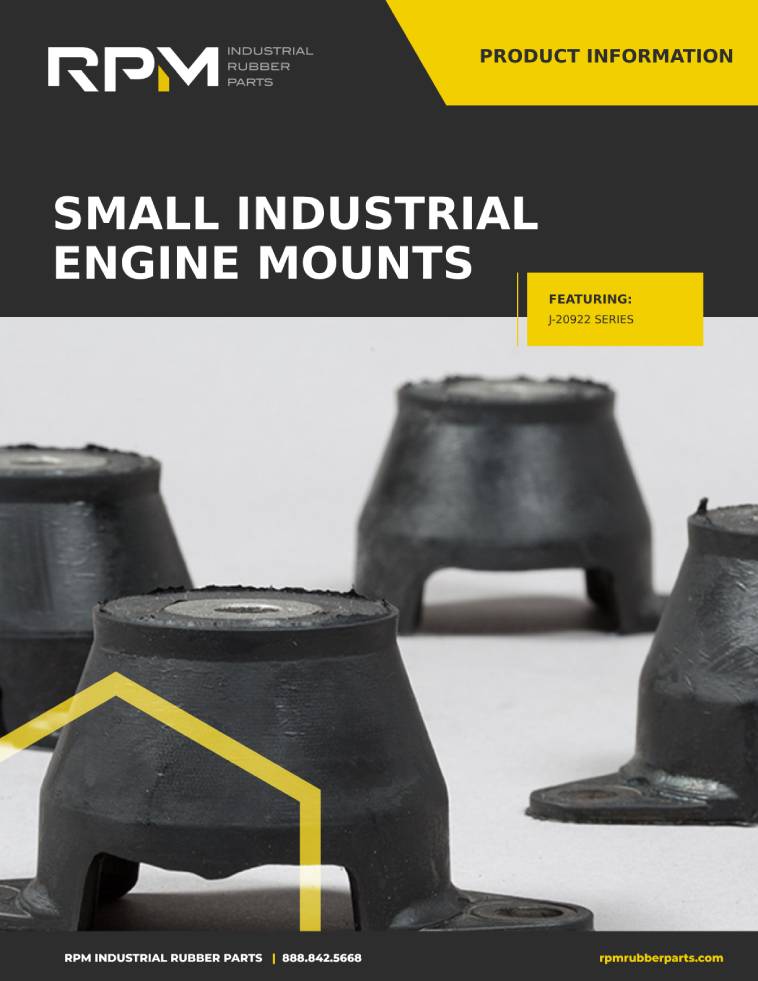

Designed to minimize vibration, absorb shock, and dampen noise from structure-borne sources, RPM’s Center Bonded Mounts provide dependable protection for equipment operating in tough conditions. These rugged mounts effectively cushion impacts, eliminate metal-to-metal contact, and enhance overall stability—extending both equipment lifespan and operator comfort.

Built for versatility, RPM’s Center Bonded Mounts deliver a reliable, maintenance-free solution across a variety of applications. Whether deployed in automotive, marine, railroad, or industrial environments, these mounts maintain consistent performance while handling shock loads of up to 10 g’s. With a range of sizes and load capacities available, they easily adapt to diverse operational needs.

Crafted from premium materials, these mounts offer exceptional durability, noise reduction, and multi-directional vibration isolation. Their permanently bonded, one-piece construction streamlines installation, optimizes space usage, and ensures long-lasting performance—making them an efficient and cost-effective choice for mobile, transport-mounted, or portable equipment.