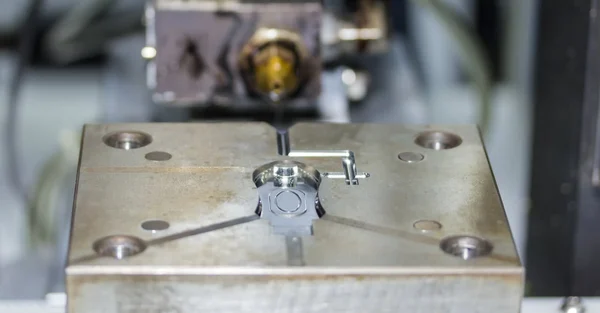

There are many different kinds of rubber molding methods, but one of the most common is injection rubber molding. Most rubber manufacturers utilize injection rubber molding to create custom and standard parts. This is an excellent method for high volume production and intricate parts. Manufacturers can choose from a variety of materials and complete rubber to metal bonding for vibration control and equipment safety.

Rubber Injection Molding Process

The injection rubber molding process is made up of a few steps. Here is how the injection rubber molding process works:

- Uncured rubber is fed into the screw of the injection molding machine

- Uncured rubber is pulled into the injector

- The uncured rubber is liquidized at a high temperature

- The liquid polymer is injected into the injection mold cavity through a runner and gate

- The rubber material is cured and vulcanized at a high pressure and temperature

- The rubber part is removed from the mold cavity

The machine that is used to create injection molded rubber parts is fairly large. However, it is able to manufacture a rubber product at high speed and precision, making it an excellent way to mass produce any kind of rubber part required.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Materials for Injection Molding

One thing that manufacturers love about injection rubber molding is the ability to use a variety of materials. When it comes to rubber molding, manufacturers will choose from a few different polymers:

- Natural Rubber

- Silicone

- Nitrile Rubber

- Fluorosilicone

- Liquid Silicone Rubber

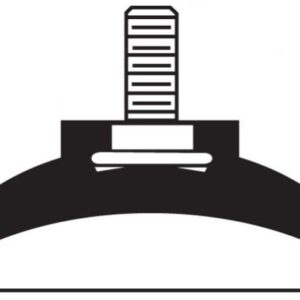

Most commonly, the rubber gaskets or other rubber or polymer parts will be used for vibration control or to protect machines. Whatever their ultimate use, they are typically put into operation after being bonded to the equipment or a mount. This is called rubber to metal bonding. Here are some of the most common metals used for rubber to metal bonding in injection molding:

- Aluminum

- Copper

- Brass

- Steel

- Beryllium

A manufacturer will choose a material depending on its intended use and the properties it needs to have and maintain. If the part needs to be strong and durable, they may choose a nitrile rubber rather than a silicone.

Advantages of Injection Rubber Molding

BecaThere are many benefits to using injection molding over compression molding or transfer molding. Here is a list of some of these benefits:

- High precision

- Allows for more intricate designs

- Quick cycle time

- Elimination of preforms

- Less flash and rubber waste

- More options for durometer shores

- Fits almost exactly to the mold

- Great for high volume production needs

Companies that want to produce a high volume of quality parts in a short amount of time should choose injection rubber molding. With injection molding, OEMs get their part quickly and customers get a quality product.

Disadvantages of Injection Rubber Molding

Injection rubber molding is not always the best choice for every part. Some manufacturers prefer to use compression or transfer molding instead. These are some of the disadvantages of using injection rubber molding:

- Machinery is more expensive than other molding machines

- Not well suited for small batches

- Some elastomers are not suited for injection molding

- Works best for small parts rather than large parts

Sometimes, injection rubber molding is not the right option. For example, if a manufacturer is trying to mold a tire, then injection molding may not be the right method. Smaller sized, high volume parts are best for injection rubber molding.

Injection Rubber Molding Applications and Industries

There are many uses for parts that are created using injection molding. Here is a list of some of the industries that use injection molded rubber parts and what they use them for:

- Construction: seals, gaskets, vibration control, grommets, tubing

- Automotive: transmission, engine parts, valves, extrusions

- Defense: weapon parts, vibration, noise control, seals

- Mass Transit: brakes, steering, tubing, electrical wiring covers, engine parts

- Medical: tubing, ventilation masks, medical equipment, seals

- Agriculture: seals, vibration control, noise control, bushings, suspension

There are many different uses for molded rubber parts. Some manufacturers even produce custom parts so that OEMs can receive the exact part that they need

Custom Molded Rubber Manufacturer

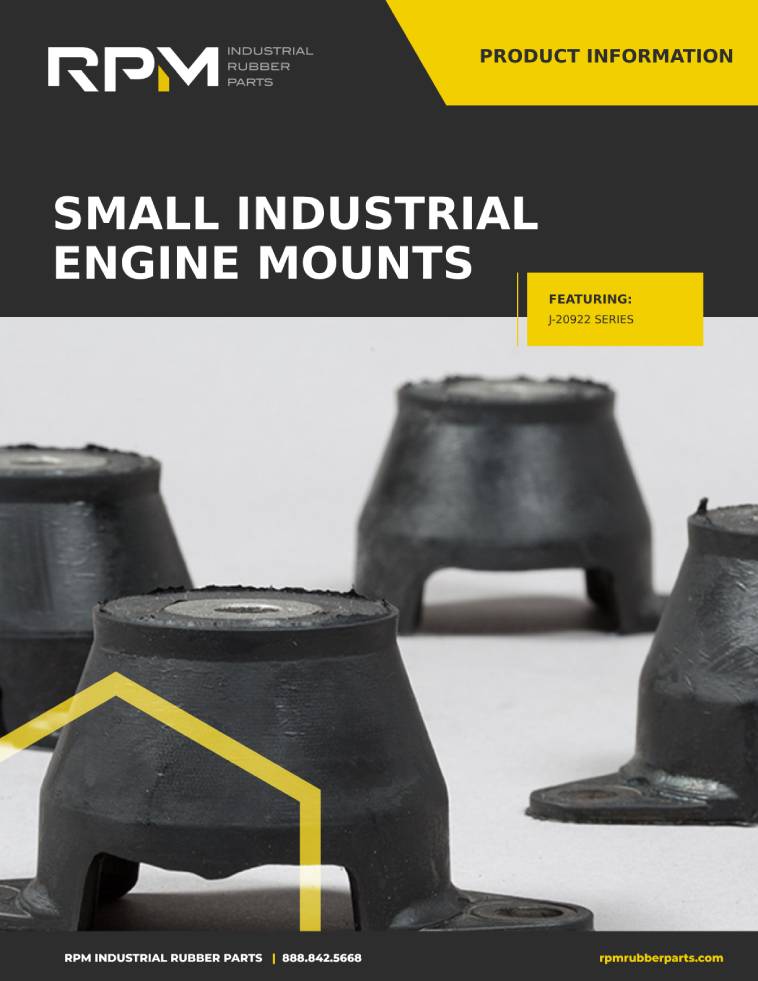

One common way that manufacturers produce high volume custom parts is through injection molding. If you are looking for a company that produces high quality custom parts and standard parts, look no further than RPM Industrial Rubber Parts. We have a long list of parts in our catalog, including:

- Grommets

- Bushings

- Seals

- Vibration Control

- Extrusions & Tubing

If you cannot find what you need, then you can get it custom made with our team. We will walk you through the process so that you are completely satisfied with the final result. To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.