Vibration isolation plays a critical role in various industries, from automotive to agriculture and beyond. The effectiveness of vibration isolation solutions significantly impacts the performance, longevity, and safety of machinery and structures. Rubber mounts, with their unique properties, have emerged as indispensable components in mitigating vibrations across diverse frequency ranges. This article explores the principles behind optimizing vibration isolation using rubber mounts and highlights their significance in enhancing operational efficiency and reducing structural fatigue.

Understanding Vibration Isolation

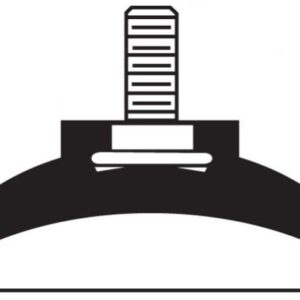

Vibration isolation aims to minimize the transmission of unwanted vibrations from a source to its surroundings or other components. This process involves disrupting the path of vibration energy through the use of resilient materials or damping mechanisms. Rubber mounts, also known as rubber isolators or vibration mounts, are widely preferred for their ability to absorb and dissipate vibrations effectively.

Do you really know everything about designing with rubber parts?

Get a free and valuable resource for finding or custom designing the exact part you need.

Optimizing Vibration Isolation Across Frequency Ranges

Rubber mounts exhibit different performance characteristics depending on the frequency of the vibrations they encounter. Achieving optimal vibration isolation across various frequency ranges requires careful consideration of several factors:

1. Material Selection

The material composition of rubber mounts greatly influences their vibration isolation capabilities. Natural rubber vs. synthetic rubbers with varying hardness and damping properties are commonly used. Selecting the appropriate material based on the frequency range of the vibrations ensures optimal performance.

2. Resonance Frequency

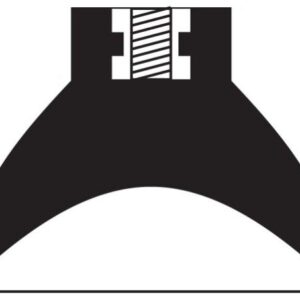

Every rubber mount has a resonance frequency at which it exhibits maximum vibration isolation efficiency. Below this frequency, the mount effectively isolates vibrations, while above it, the effectiveness decreases. By matching the resonance frequency of the mount to the predominant frequencies of the system, engineers can achieve peak performance in vibration isolation.

3. Dynamic Stiffness

Dynamic stiffness refers to the stiffness of a rubber mount under dynamic loading conditions. It varies with frequency, and optimizing dynamic stiffness across different frequency ranges is crucial for effective vibration isolation. By adjusting the design parameters such as geometry and material properties, engineers can tailor the dynamic stiffness to suit specific application requirements.

4. Dampening Characteristics

Rubber mounts dissipate vibration energy primarily through internal damping mechanisms. The damping characteristics, often quantified by the loss factor or damping ratio, determine the amount of energy absorbed by the mount. Balancing stiffness and damping properties is essential for achieving optimal vibration isolation across a wide range of frequencies.

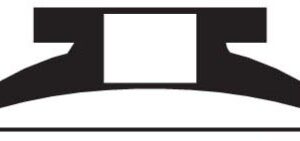

5. Multi-Stage Mounting Systems

In applications with broad frequency spectra or complex vibration profiles, employing multi-stage mounting systems can enhance isolation performance. By combining rubber mounts with different resonance frequencies and damping properties in series or parallel configurations, engineers can effectively attenuate vibrations across diverse frequency ranges.

Significance in Industrial Applications

The optimization of vibration isolation using rubber mounts holds significant implications across various industrial sectors:

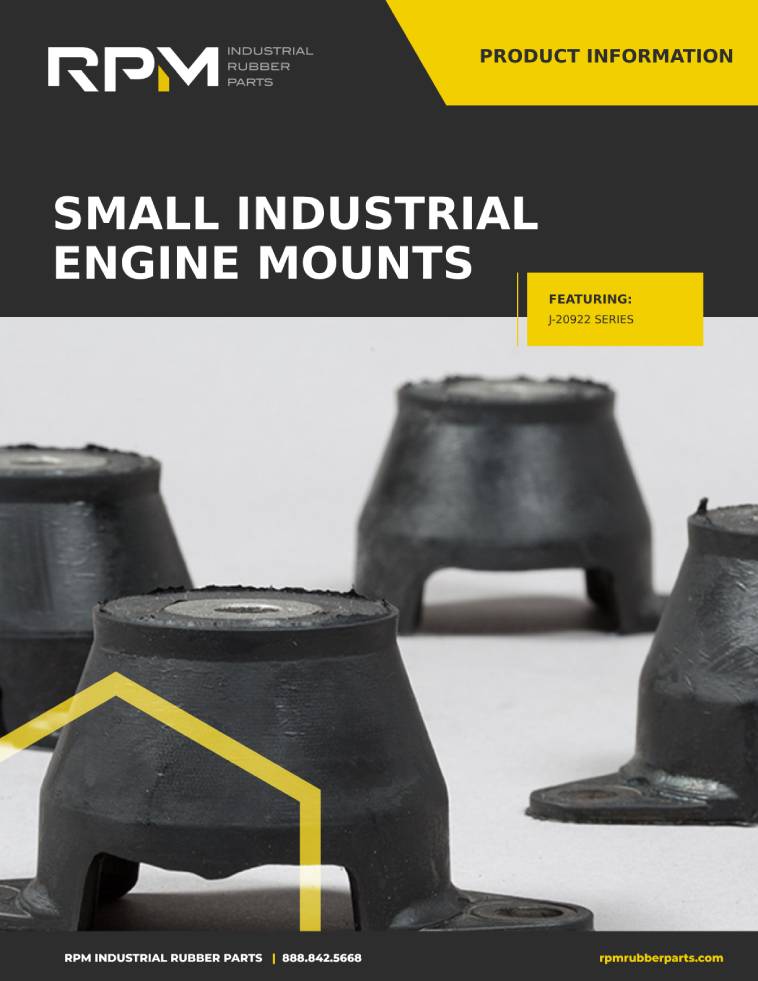

- Automotive Engineering: In vehicles, rubber mounts isolate engine vibrations, road-induced vibrations, and other sources of mechanical oscillations. By fine-tuning the properties of rubber mounts, automakers enhance ride comfort, reduce noise levels, and improve vehicle durability.

- Machinery and Equipment: Industrial machinery and equipment often generate vibrations that can compromise precision, reliability, and worker safety. Rubber mounts provide cost-effective solutions for isolating these vibrations, thereby extending machinery lifespan and minimizing maintenance requirements.

- Defense: In defense applications, where mission success and personnel safety are paramount, vibration isolation is critical. Rubber mounts play a crucial role in isolating vibrations generated by sensitive equipment, such as radar systems, communication devices, and weapon platforms, ensuring optimal performance and operational effectiveness.

Optimizing vibration isolation across frequency ranges using rubber mounts is a multifaceted endeavor that requires careful consideration of material properties, resonance characteristics, and damping behavior. By leveraging the inherent flexibility and damping capabilities of rubber, engineers can design robust isolation systems capable of enhancing performance, reliability, and safety across diverse industrial applications.

As technology advances and engineering practices evolve, the role of rubber mounts in vibration mitigation is likely to continue expanding, driving innovation and efficiency across multiple sectors.

At RPM Industrial Rubber Parts, we make it our top priority to find the exact part that you need. If we can’t find it, we’ll make it for you. With our custom molded rubber part service, you will work with our team of designers and engineers to turn your idea into reality.

To get in touch with our team at RPM Industrial Rubber Parts, give us a call at (888) 842-5668 or contact us online.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.