Markets Served

Rubber Parts For The Agriculture Industry

Farming is a time-sensitive occupation. Crops have specific windows of time that they can be planted and harvested. This is why it is so important that farming equipment works when needed. A faulty machine can result in missing important deadlines and potentially impacting total crop yield. More +

Rubber Parts & Agriculture Equipment Applications

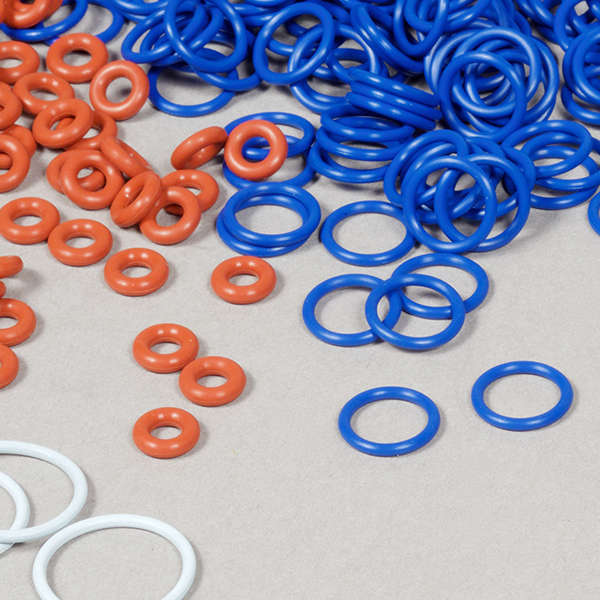

RPM offers advanced rubber molding solutions tailored to meet precise specifications and industry standards. With expertise in compression, transfer, and injection molding, we deliver high-quality, durable rubber components designed for agriculture applications.

| Application | Common Parts | Common Processes |

|---|---|---|

| Tractors | Rubber seals, vibration mounts, grommets, and bushings used to reduce noise and protect components and enhance operator comfort. | Compression molding for durability and high resistance to tearing, injection molding for complex shapes and precise tolerances. |

| Wheel Loaders | Door/compartment seals, rubberized flooring, engine mounts, and rubber bumpers to ensure safety and comfort for operators and protect equipment from damage. | Transfer molding to create durable, shock-absorbing parts, extrusion for flexible seals and tubing. |

| Plows | Engine Mounts, anti-vibration pads, and rubber bushings designed to protect equipment from impact and abrasion and improve operator comfort. | Precision extrusion for high-quality seals, vulcanization for enhanced material properties like heat and wear resistance. |

| Balers | Rubber buffers, hydraulic seals, door/compartment seals, vibration dampeners, rubber grommets, and protective boots for control levers etc. | Compression molding for long-lasting durability, injection molding for custom shapes and parts, die-cutting for precise component production. |

| Combines & Harvesters | Rubber buffers, hydraulic seals, protective boots, and rubberized mats to maintain equipment longevity and enhance safety. | Injection molding for intricate parts, precision die-cutting for custom shapes, and vulcanization for improved mechanical properties. Compression molding for durability and high resistance to tearing. |

| Backhoe | Shock-absorbing rubber pads, high-impact seals, dust boots, and vibration control mounts used to withstand harsh off-road environments. | Compression molding for robust, wear-resistant parts, transfer molding for strong, flexible components, vulcanization for enhanced impact and abrasion resistance. |

| Crop Sprayers | Rubberized cable protectors, shock-absorbing mounts, impact-resistant seals, and gaskets to protect equipment and provide safe hadling of pesticides etc. | Injection molding for high-precision parts, compression molding for impact resistance, vulcanization for enhancing durability and safety properties under high-stress conditions. |

Use our interactive infographic to find rubber parts for your Agriculture application:

At RPM Industrial Rubber Parts, we pride ourselves on providing quality customer service. Whether you need a standard part to replace an old one or are designing out-of-the-box machinery that requires custom parts, our team can ensure you get the exact part you need.

Off-Road Vehicle OEM’s Guide

Our free resource provides detailed information on sandwich mounts, vibration isolation analysis, mounting strategies, and more.

Challenges

According to the US Department of Agriculture, small farms (profits of less than $250k) account for 91% of all farms in the United States. However, large farms (profits of more than $250k), account for 85% of agricultural production. Regardless of size, there are common challenges:

Productivity

Increasing productivity in farming equipment means increasing the quality of the product. When rubber vibration control products are implemented into agricultural machinery, they last longer and become more efficient. Whether using a standard tractor or the newest, most technologically advanced combine, farms are looking for durability that lasts.

Reliability

Various agriculture tasks are time sensitive. Equipment needs to be durable and reliable to ensure planting, fertilization, harvesting, etc. are all done at the optimum time. Providing shock and vibration control rubber parts will ensure equipment functions long-term.

Labor

Small farms are looking to optimize acreage and grow commodities with little labor. Large farms look towards equipment that can complete more than one task with one operator.

Trends

With an increasing world population growth, our ability to feed billions of people relies on the improvement of agricultural equipment so that farmers can produce higher yields. Incredible technological breakthroughs are happening in this industry – although some are more accessible than others. Take a look at these exciting trends in farming machinery:

Autonomous Agriculture Robots

The use of robots in agriculture and farming is growing. These autonomous machines are designed for tasks such as weeding, crop picking, pest and disease detection, seed planting, and soil sampling. Many of these robots utilize a variety of sensors to learn about the environment around them. This could include visual sensors that help them follow planted rows or to detect water and air pressure changes. Sensors can become easily damaged when they are not protected. Providing shock and vibration control rubber parts for sensors will ensure long-term function.

Technologically Enabled Machinery

Technologically enabled farming equipment is similar to standard farming equipment, but with added advanced features that can help improve crop yield and reduce product waste. The equipment’s critical sensors and electronics need to be isolated and protected. Rubber technology is perfect to solve these challenges. Understanding vibration isolation theory and why it matters is key to protecting sensitive precision equipment.

Related Resource

The Engineer’s 7-minute Guide to Rubber Molded Parts

Our free resource is a quick-reference guide to help you determine if exploring a rubber part is right for your application.

Frequently Asked Questions

Find quick answers to your questions here or contact us directly for any additional inquiries.

What are the benefits of rubber compression molding?

Compression molding offers several advantages, including high production rates, excellent dimensional stability, and the ability to produce complex shapes with intricate details.

Which is better? Natural rubber or synthetic rubber?

Natural and synthetic rubbers each have strengths. Natural rubber is great for flexibility, while synthetic rubbers can be customized for specific needs like heat resistance. The best choice depends on the specific application.

How do I select a vibration isolator for my application?

To select the right vibration isolator, start by determining the frequency and amplitude of the vibrations, the weight of the equipment, and the desired level of isolation. Contact the team at RPM for assistance.

What is rubber-to-metal bonding?

Rubber-to-metal bonding involves creating a strong and durable connection between rubber and a metal surface, resulting in a composite material that combines the flexibility and shock absorption of rubber with the strength and rigidity of metal.

What is an engine mount and how does it work?

An engine mount is a flexible component that isolates the engine from the vehicle’s frame, reducing vibrations and noise while allowing for slight engine movement during operation.

What is a rubber sandwich mount?

A rubber sandwich mount is a vibration isolation device consisting of two metal plates with a layer of rubber sandwiched between them, used to reduce the transmission of vibrations.

Ready to get started?

Let Us Be a Small Part of a Big Solution: Your Partner in Building Life Changing Products.

Or Call Us: 888-842-5668